Welcome to Phoenix’s documentation!¶

Below is the latest documentation for CTR-Electronics Phoenix software framework. This includes…

Class library for Talon SRX, Talon FX, Victor SPX, CANCoder, CANifier and Pigeon-IMU (C++/Java/LabVIEW for FRC, C# for HERO)

Phoenix Tuner Graphical Interface - provides configuration options, diagnostics, control and plotting.

Phoenix Diagnostic Server - install on to roboRIO for Tuner, and to perform HTTP API requests for diagnostic information.

Blog Entries¶

Jan 08, 2021 - BLOG: FRC 2021 Kickoff

Feb 20, 2020 - BLOG: Falcon 500 / Talon FX Critical Update

Jan 04, 2020 - BLOG: FRC 2020 Kickoff

Mar 09, 2019 - BLOG: RoboRIO Performance Insight and Optional Phoenix 5.14.1 Update

Feb 16, 2019 - BLOG: FRC 2019 Week 6

Feb 01, 2019 - BLOG: FRC 2019 Week 4

Jan 11, 2019 - BLOG: FRC 2019 Week 1

Jan 04, 2019 - BLOG: FRC 2019 Kickoff

Dec 16, 2018 - Site Created

Follow these instructions in order!¶

FRC Blogs¶

BLOG: FRC 2021 Kickoff¶

Hello FRC Community!

We’ve just released our 2021 kickoff release of Phoenix Framework (5.19.4.1). The Phoenix Windows installer and zips for macOS and Linux are now available.

You can find the latest firmware CRFs at each product page (the installer also installs them).

The new features included in this season’s release are listed below.

Simulation Support¶

We’ve spent our offseason investing in a new suite of simulation features designed to allow effective development without requiring access to hardware.

This includes:

Simulation of device-level features, such as Motion Magic

Full feature support of Phoenix Tuner (including Plotter, Self Test Snapshot, Control, and Configs)

Support for simulated device-to-device features, such as follower mode and remote sensors/limit-switches

Integration with WPILib’s simulation GUI when using WPI_* classes

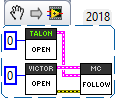

Supported Devices: Talon SRX, Victor SPX (future releases will include more devices)

Supported Operating Systems: Windows, Linux, macOS

Supported Languages: Java, C++

If you encounter any limitations with Talon SRX or Victor SPX simulation, please contact support@ctr-electronics.com or file an issue tracker here.

Phoenix Simulation Examples¶

For teams that want to start leveraging simulation features right now, the basic steps are:

Check out one of our examples that supports simulation (such as the Motion Magic example).

Open the example in Visual Studio Code and run in simulation.

Open Phoenix Tuner and set the Diagnostic Server Address to

localhost. Simulated devices will appear in Phoenix Tuner in a few seconds.Develop as normal.

Tip

We invite teams to leverage their preferred physics simulators by utilizing the SimCollection functions in Talon SRX and Victor SPX as seen here.

Note

Simulating non-FRC applications (not using WPI_* classes) will require calling Unmanaged.feedEnable(100); to enable simulated actuators.

Additional documentation for simulation will be available in the future.

Online API Documentation¶

The online API documentation has been updated for 2021.

C++ documentation can be found here.

Java documentation can be found here.

Java teams should note that the documentation jar is installed locally after running our installer.

LabVIEW¶

No new functionality has been added to Phoenix for LabVIEW users this season.

Release Testing Observations¶

During our release testing process, we observed the following limitations:

roboRIO 2021 v3.1 Image¶

We observed that we could not reliably image our roboRIOs with the 2021 v3.1 image. As a result, all of our testing has been done using the 2021 v3.0 image.

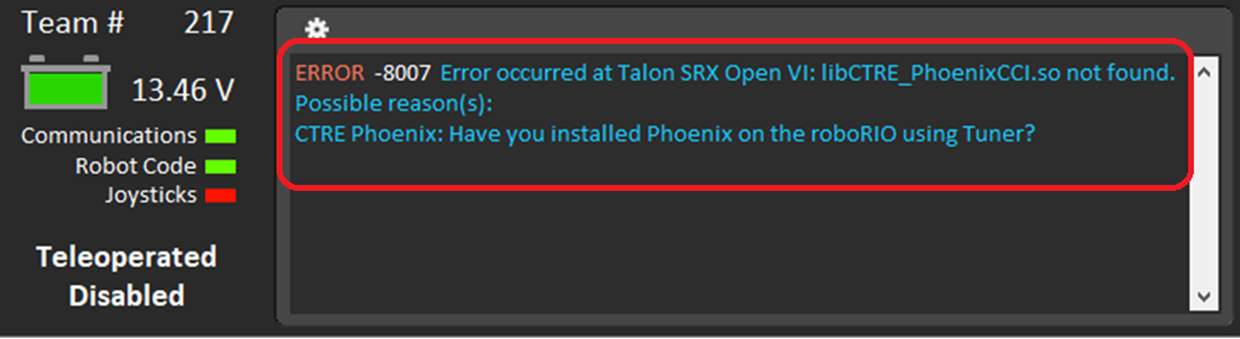

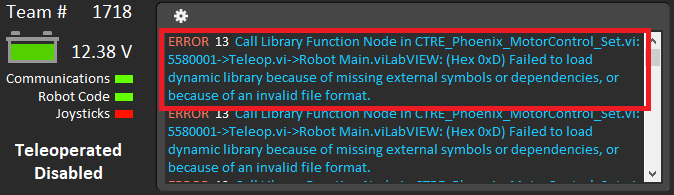

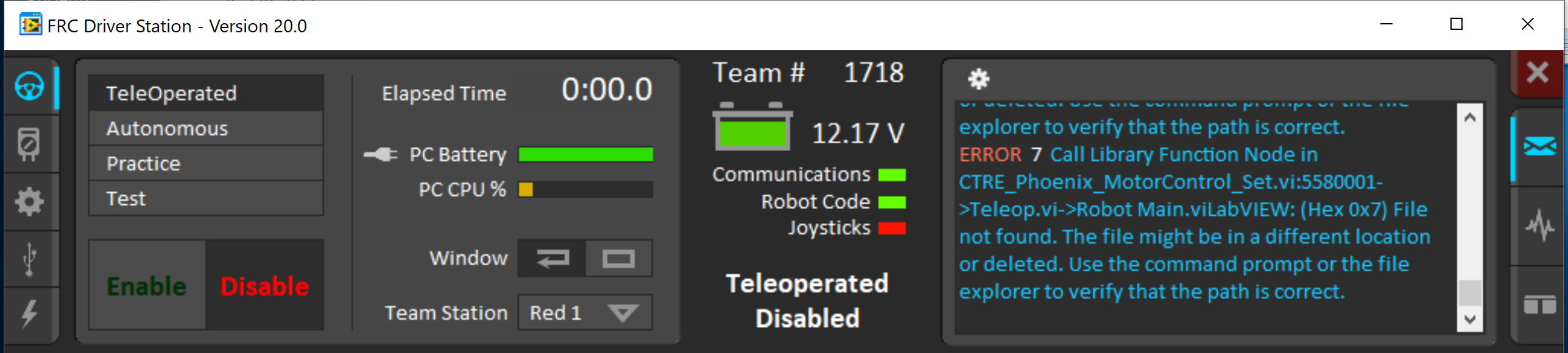

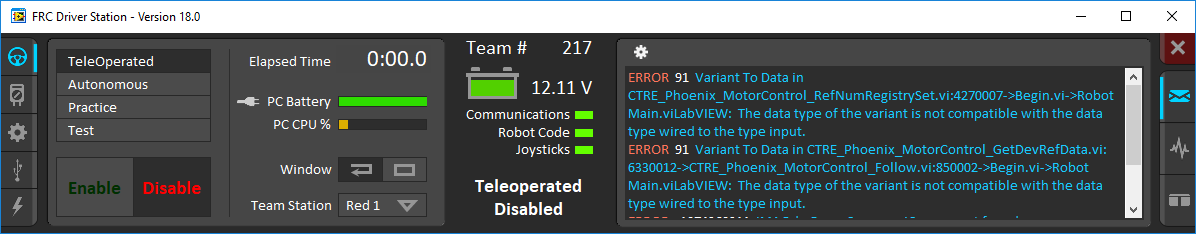

LabVIEW Deploy Limitation¶

We have noticed an intermittent issue that corrupts the Phoenix library files during LabVIEW deploy. This is reproduced by the following procedure:

Soft deploy your application (clicking the white arrow in Main.vi or <Ctrl>+R)

Hard deploy your application (right-click “FRC Robot Boot-up Deployment”, Run As Startup)

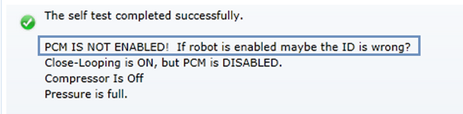

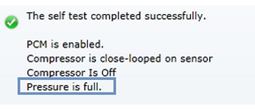

This dialog pops up when the issue occurs:

To solve this issue, hard deploy your application again.

Back-breaking API changes¶

In anticipation of future releases that support custom unit scaling, several of the Java and C++ routines have been updated to use doubles instead of ints.

We have also removed routines that have been deprecated for multiple seasons.

Removed motor controller routines:

set(ControlMode, double, double)

enableHeadingHold(bool)

selectDemandType(bool)

getActiveTrajectoryHeading()

Removed PigeonIMU routine:

configTemperatureCompensationEnable(bool, int)

Firmware¶

There are some new firmware files for this season. However, they are not required for general functionality.

A maintenance release (v21.0) for Falcon 500 (Talon FX), Talon SRX, and Victor SPX is available at each product page (the installer also installs them).

Good luck, and stay safe! - The CTRE Engineering Team

BLOG: Falcon 500 / Talon FX Critical Update¶

Hello FRC Community!

We’ve just released Phoenix API 5.18.2.1 to address a reported issue with Falcon 500 (Talon FX). This release requires the new Talon FX firmware (20.3.0.2). The Phoenix installer and non-Windows binary kit is now available.

You can also find the latest firmware CRFs at each product page (the installer also installs them).

New Talon FX Firmware 20.3.0.2¶

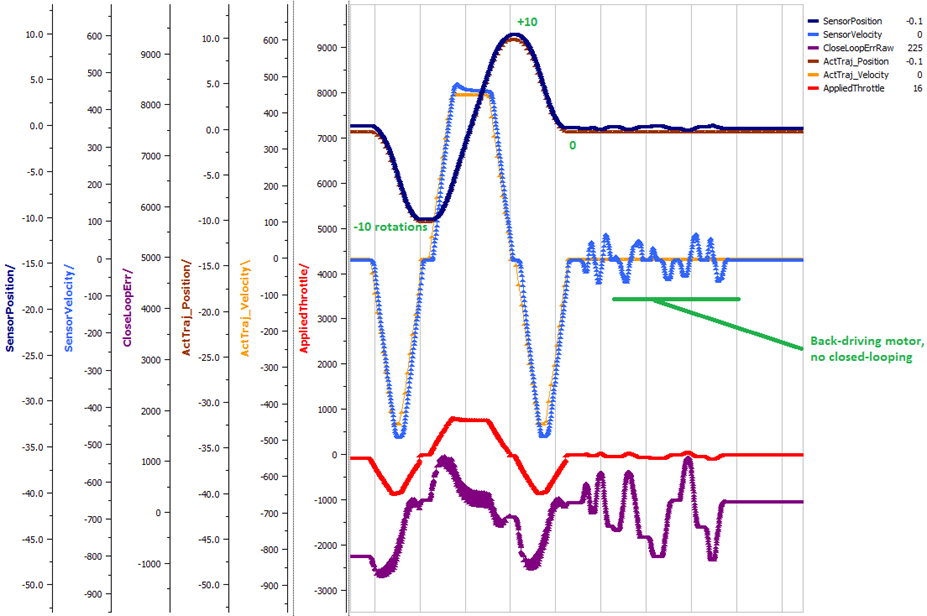

We received a small number of Falcon RMAs with a unique failure mode. After failure analysis, we found a circumstance where the tank capacitors inside the Talon FX can be damaged if certain conditions are met. The conditions require the following (for several seconds):

Disconnecting Falcon from battery (open breaker event or disconnect power harness from battery)

Back-driving the Falcon’s rotor above 3500 RPM (which will power up the electronics within the Falcon)

At least one of the following.

Commanding Falcon to drive motor while continuing to back drive Falcon above 3500 RPM.

Commanding neutral-brake while continuing to back drive Falcon above 3500 RPM.

These conditions can also be harmful with brushed motor controllers (3a in particular), but what makes Falcon unique is that:

it is a far more efficient generator than previous generation FRC controllers

condition 3.B. is unique to Falcon since it conditionally modulates neutral-brake during high-current events, which can exacerbate the issue.

The firmware update referenced above addresses this by detecting when these failure conditions occur). Motor output/brake will be disabled in this state, until the Falcon is properly powered again (breaker closes or supply brought back in circuit). When this occurs, Talon FX will blink a fault pattern (similar to thermal limit but green instead of orange).

Tip

You can still back-drive your robots when they are powered off (pushing an unpowered robot from one location to another is common). Manually back-driving does not reproduce this failure as this does not create enough energy, nor does it allow robot to be enabled for motor drive.

There will be two new faults to detect this condition:

Supply Unstable Voltage - reflects the motor controller’s inability to stabilize voltage due to the battery not being in circuit.

Supply Overvoltage - reflects the motor controller’s inability to prevent voltage from escalating well above the rated max voltage due to regenerative braking while battery is not in circuit.

Both are accessible via the fault API and Tuner Self-test Snapshot.

Note

Faults do not need to be cleared to resume normal functionality (faults are instrumentation only):

Warning

Because this firmware fix involves preventing a hardware damaging condition, the latest API release will require this version or newer to control Talon FX.

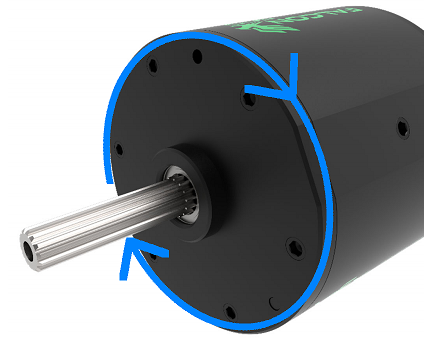

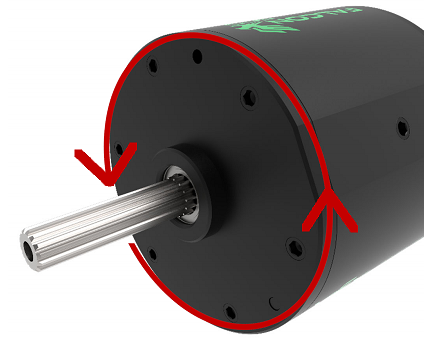

Falcon 500 Shaft Retention Screws¶

There have been recent reports of Falcons with insufficient Loctite on the shaft screws. VEX has released the following recommendation to apply Loctite to this seasons Falcons.

Warning

Note: We’ve found that some Falcons built during the first year (date code beginning in 19 or 200) may not have had Loctite properly applied to the shaft retaining screws. To be safe, we recommend that teams with first year motors open up them up and reapply Loctite 243 to all the shaft retention screws.

Documentation will be updated in various places to reflect this.

We strongly recommend teams inspect Falcons that are in use.

Future Firmware update - Talon FX / Falcon¶

We have one recent documented occurrence where if the Talon FX’s supply voltage drops to a narrow margin (4.6 - 4.8 V) and recovers, the Talon FX can be fooled into reporting a hardware fault (which causes a perpetual red/orange blink pattern).

This is not a typical voltage band to operate in. Talon FX has voltage monitoring features that prevent this in the majority of cases (even when using a depleted battery). However improper power wiring can cause this issue to occur (for example: Falcon red and black leads shorting to each other momentarily).

We’ve reproduced this and will have a firmware update coming to address it. It wasn’t released in time for today’s release, but should be out shortly.

EDIT: Fix is now available at https://github.com/CrossTheRoadElec/Phoenix-Releases/releases/tag/firm_FX_v20.4.1.0

BLOG: FRC 2020 Kickoff¶

Hello FRC Community!

We’ve just release our 2020 version of Phoenix API 5.17.3.1. The Phoenix installer and non-Windows binary kit is now available.

You can also find the latest firmware CRFs at each product page (the installer also installs them).

The new features included in this season’s release are listed below.

New Product - Talon FX¶

The biggest addition to the Phoenix software library is support for the new brushless integrated motor/motor-controller: The Talon FX (Falcon 500). Although this is a new product featuring several unique features, we developed the product in a way where the TalonSRX class can still be used to control the device. We believe this will allow teams to quickly integrate the new motor controller into their robots.

Additionally a new class called TalonFX has been added to the project. The API is very similar to the Talon SRX with the following differences:

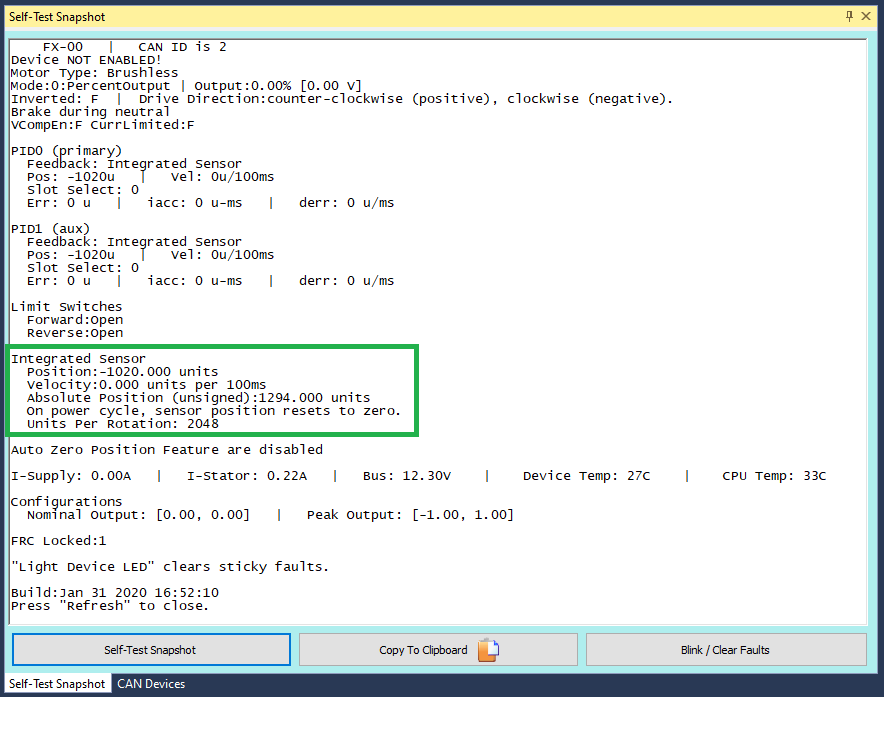

TalonFX’s integrated sensor has a native resolution of 2048 units per rotation regardless of which class is used.

TalonFX’s default sensor type defaults to the integrated sensor (not quadrature).

TalonFX additionally supports TalonFXFeedbackDevice, to self-document the sensor types which are supported.

TalonFX additionally supports TalonFXControlMode (allowing future Talon FX specific control modes).

TalonFX allows simultaneous limiting of both stator (output) and supply (input) current.

New Product - CANCoder¶

The other major addition to our supported product list is CANCoder. The CANCoder is the next iteration of the popular CTRE Magnetic Encoder. Many aspects of the software was driven based on what we’ve learned in supporting the Mag Encoder.

Software features include:

The ability to choose how the Absolute Position is interpreted (±180 deg vs 360 deg).

The ability to manually offset the magnet position. This allows you to move inconvenient discontinuities outside of your mechanism’s operational range.

Simultaneous reporting of both the “relative” position and the “absolute position”. This means you can treat CANCoder as a relative sensor, then sync it again to become absolute.

Basic Phoenix Tuner features (device discovery, field-upgrade,id assignment, id conflict resolving, configs, etc.)

Customizable units string, coefficient, and time base (per second, per min) that work across Tuner and API.

Timestamped signal updates.

Support in all three FRC languages.

NI RoboRIO CAN Bus improvements¶

Some of you may have heard of the low level modifications done to the roboRIO CAN Bus software for 2020. This was to address some of the performance concerns brought on by teams in the previous season. For those not familiar, feel free to reference this blog entry discussing the performance limitations of the roboRIO when it comes to CAN bus.

Fortunately our friends at National Instruments have found a method to allow for faster calls to the CAN bus, allowing more CAN bus calls without slowing down your roboRIO loops. Even better, this was done in a way that doesn’t require fundamental changes to the higher level software leveraging CAN bus.

This means that this performance boost plus the buffering features of Phoenix allows for the best call performance for supported CAN bus peripherals to date.

However, as a result of these changes, the initial setup for Phoenix Tuner does change a bit. This is covered in detail below.

Phoenix Tuner 2020¶

In the past, users typically “install” our diagnostics software into the roboRIO in order to leverage Tuner features. As a result of the CAN changes, the diagnostic features have been moved into a library that is linked against the robot application. This means your Phoenix diagnostics will update any time you update the API.

However Tuner is typically used during hardware bring-up, long before any software is written. As such, Tuner is now capable of deploying a simple FRC application that will allow for Tuner use. Then once you’ve started deploying your own applications, Tuner will use the Phoenix libraries in your application to fulfill the same needs.

It’s a bit different than the previously season’s workflow, but we believe it will be worth the performance gains.

Online API Documentation¶

The online API documentation has not been updated yet, but it will be soon. Java teams should note that the documentation-jar is already installed locally after running our installer.

Back-breaking API changes¶

No back-breaking changes have been logged.

Good luck this build season! - Omar Zrien

BLOG: RoboRIO Performance Insight and Optional Phoenix 5.14.1 Update¶

Hello FRC Community!

There’s been several questions about the performance limitations of the roboRIO this season, particularly in regard to CAN-bus. In response to this, we’d like to provide some insight to better educate teams on the limitations of the control system. Additionally we made some tuning adjustments in Phoenix to help alleviate the symptoms caused by these limitations.

Please read the sections below for more information.

Omar Zrien Co-owner CTR-Electronics

roboRIO Limitations (“net comm”)¶

The roboRIO has a limitation where there is delay with every call that goes to the NI Network Communication process (often called “FRC NetComm”). This includes:

sending/receiving CAN

getting team/match info (see note below)

getting joystick data (see note below)

Generally anything involving the Driver Station software. (see note below)

Generally anything not from the FPGA.

Note

Most (but not all) of these are buffered in WPI C++/Java so they actually get called once every ~20 ms, regardless of how often you call getters. However the LabVIEW VIs appear to not be buffered and may experience this call delay.

These calls average approximately 0.3 milliseconds. Many of you may think that does not sound like much, but consider the number of get calls you execute on your peripheral devices per loop. Ten “get” calls on ten unique devices will yield 100 calls per loop, which would be 30ms (although Phoenix has optimizations to reduce this explained below).

The worst-case call time can also be much longer, several milliseconds in fact, depending on the task management of the operating system. We’ve found these worst-case events to occur intermittently and vary depending on:

CPU load

Ethernet traffic

Threading strategies

These intermittent call-delays can occasionally trip the WPILIB Driver Station warnings:

Watchdog not fed within 0.020000s (see warning below).

Loop time of 0.02s overrun.

Warning

This is not the same as the “Watchdog” issue that was addressed in roboRIO v14. That refers to the FPGA Watchdog, which is a component of the roboRIO, not WPILIB.

Which means you may be seeing these warnings despite having reliable control of the roboRIO during teleoperated operation. These intermittent events may also impact your robot negatively if you are using a software strategy that requires deterministic timing.

Phoenix 2017 - 2018 (last season)¶

In our library, there are typically three kinds of calls: getters, setters, and config routines.

Knowing that the average call time of the FRC/NI layer is 0.3 ms, we can predict the call time for the following scenarios:

~0.3 ms per call for any get* routines.

~0.3 ms per call for any set* or enable* routines where the input has changed since previous call.

~0 ms per call for any set* or enable* routines where the inputs have not changed since previous call

~4 ms for any successful config* routines if non zero timeoutMs is passed. These should be done on robot boot.

~X ms for any timed out config* routines if X timeoutMs is passed. These should be done on robot boot.

~0.3 ms for any config* if zero timeoutMs is passed. These should be done in the robot loop, if at all (generally not necessary). Success is not determined since there is no wait-for-response checking.

~4 ms for any successful configGet*. These are generally not necessary in a typical robot application.

Phoenix 2018 - 2019 (Kickoff release)¶

Over the summer of 2018, we added further optimizations to improve this. For example calling getSelectedSensorPosition() twice in your loop will not cost 0.6ms (2 X the average call time).

This is because Phoenix knows how often signals are updated, and can judge when it is appropriate to perform the call. We had beta teams test this and they reported improved performance.

Similarly if you call getters on signals from the same signal group only one of them will experience the 0.3 ms cost, and the rest will return the buffered data (at least until enough time has elapsed to justify checking the CAN-bus).

This reduces the actual calls into “FRC NetComm” considerably.

Phoenix 2018 - 2019 (New Optional Release v5.14.1.2)¶

For these optimizations to work reliably, we have thresholds to determine when to start checking the bus again for fresh data.

The kickoff release had conservative thresholds. This was appropriate given that the performance results were improved and this was a new feature for this season. However, given the number of teams reaching the limits of the roboRIO performance, we’ve released a new version with more aggressive thresholds (5.14.1).

To be clear, there are no API changes in this release. We would not feel comfortable making those types of changes during the competition season. This is merely an optional update for teams looking for any means of squeezing more performance out of their roboRIO + CAN bus peripherals.

As with any software component update, teams should re-validate all base functionality of their robot. If this cannot be done, then do not feel obligated to apply this update as this is entirely optional.

In general we recommend that teams attempting to use software loops for time critical tasks to:

Directly measure your “dT” (time between loop calls) and compensate for the measured deviations. WPILIB and LabVIEW provide routines to measure time.

LabVIEW teams can leverage the built-in profiler to profile their robot applications.

Consider updating to 5.14.1 if roboRIO limitations are impacting robot performance.

Review the number and type of “get” calls being done per loop. For example, if retrieving current-draw and sensor position, use getSelectedSensorPosition() instead of the routines in getSensorCollection(), since selected sensor position and current-draw are in the same status group.

Consider using the hardware-accelerated features of our motor controllers (Talon SRX, Victor SPX).

Note

There is a motor controller firmware update for teams using low-resolution sensors and Motion-Magic. However if you are using the feature successfully, you likely do not need to update.

Note

Some teams have opted to use alternative platforms that do not have the same call limitations. An example of this would be using Phoenix on Raspberry-Pi/Jetson TX2. These devices function by leveraging a kernel-based CAN-bus solution (socket-can).

How To download¶

Windows users can download the v5.14.1 Installer.

Alternatively, users can download the individual components:

Release page on GitHub: https://github.com/CrossTheRoadElec/Phoenix-Releases/releases

Firmware can be downloaded from the product pages on http://oldsite.ctr-electronics.com/

Additionally teams can pull the latest Phoenix API via the online method through VS Code, or via the non-Windows zip.

Download instructions can be found here.

Note

The online method refers to the “Check for updates (online)” feature. However this is not recommended as this requires a live Internet connection to use your FRC project.

BLOG: FRC 2019 Week 6¶

Hello FRC Community!

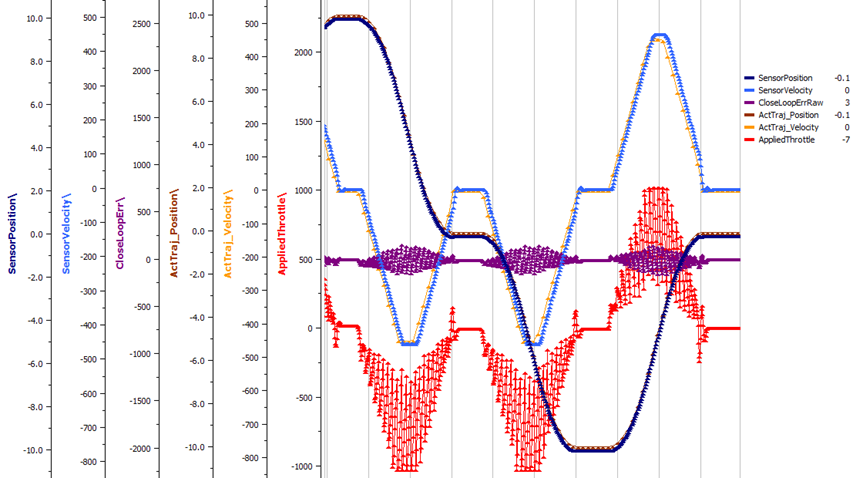

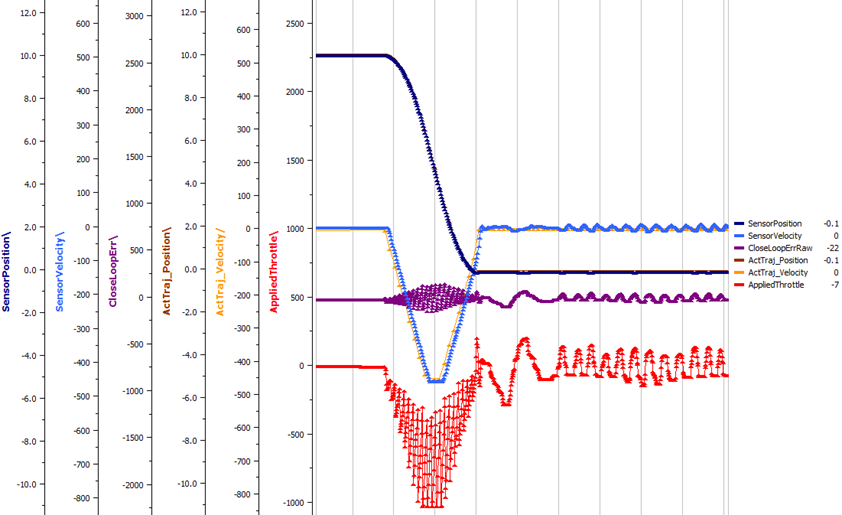

This weekend we have posted the Phoenix v5.14 feature release. This update has a few new Motion Control features we think will benefit teams as they wrap up their build seasons.

The features included are:

Talon and Victor firmware support for motion magic with S-Curve.

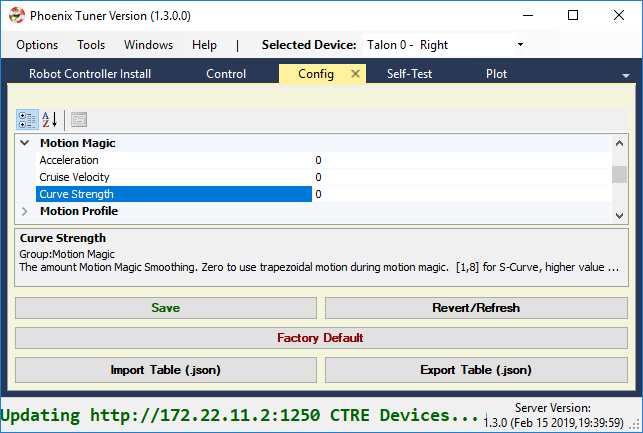

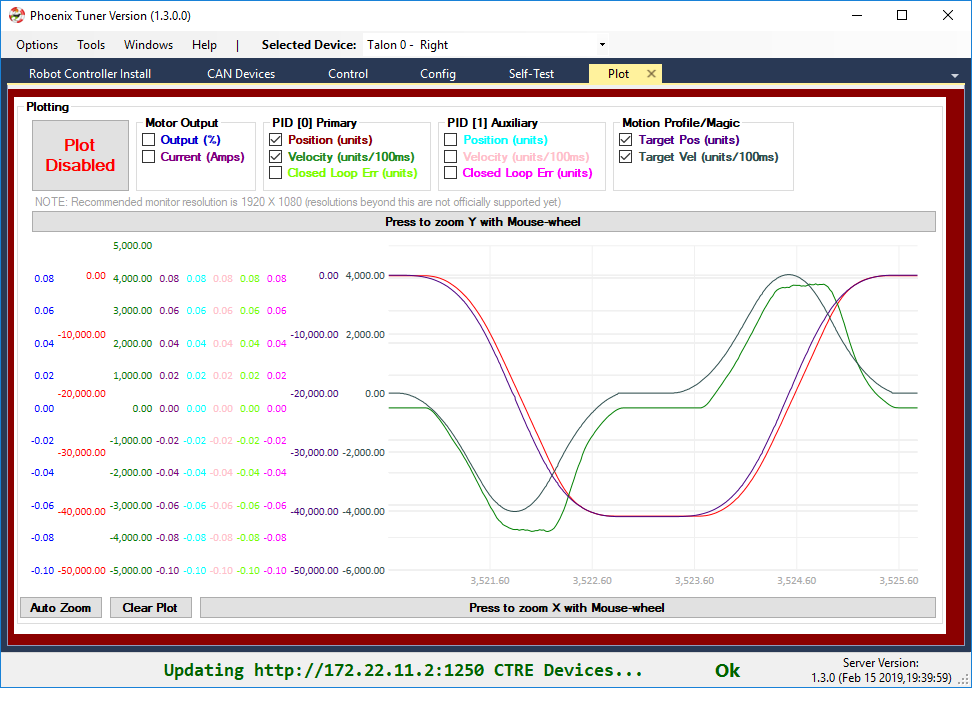

Tuner plotter can plot target position and velocity for MotionMagic/MotionProfile.

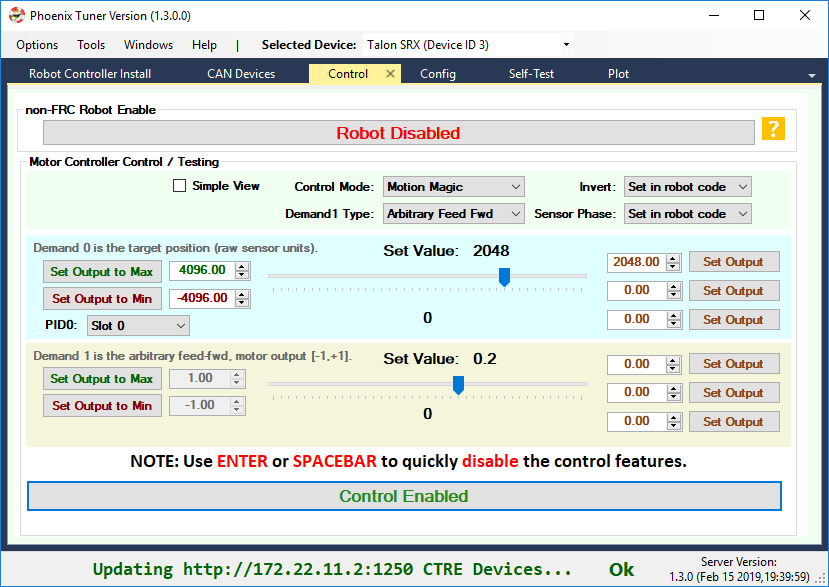

Tuner control tab supports testing several closed-loop modes including Motion Magic.

In this release the following components were updated:

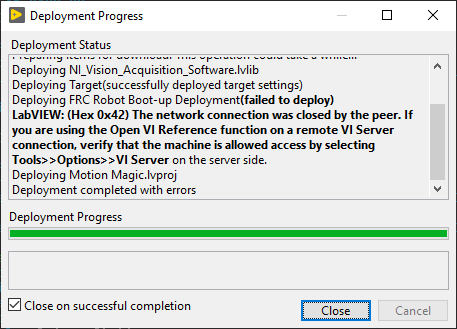

New Tuner v1.3 (with Diagnostic Server v1.3)

New Phoenix API v15.4

New Firmware for Talon SRX (4.17) and Victor SPX (4.17)

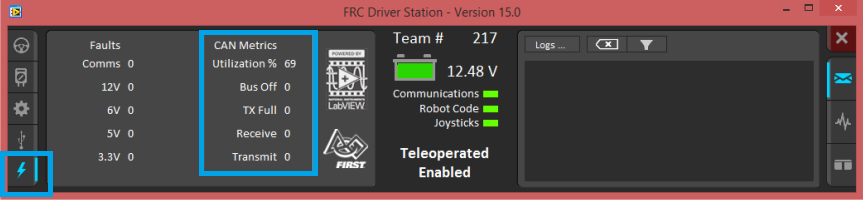

Note

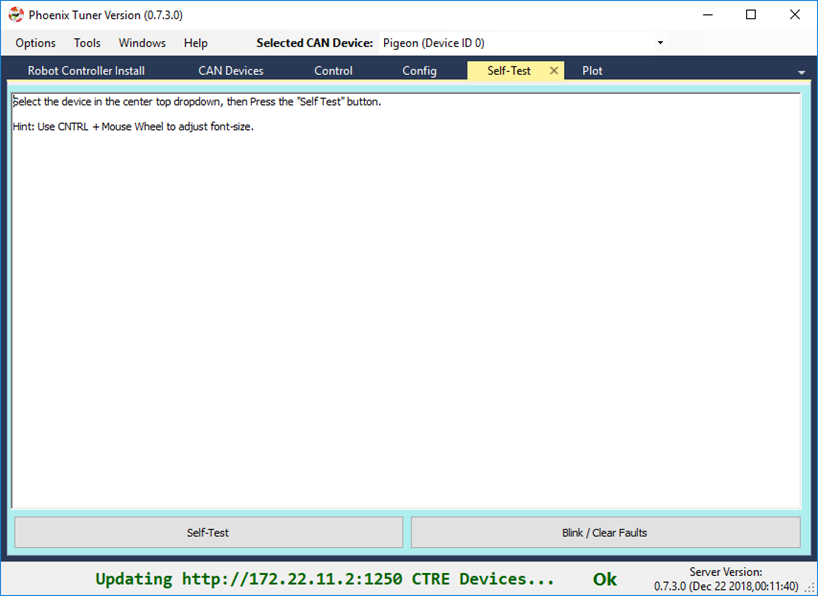

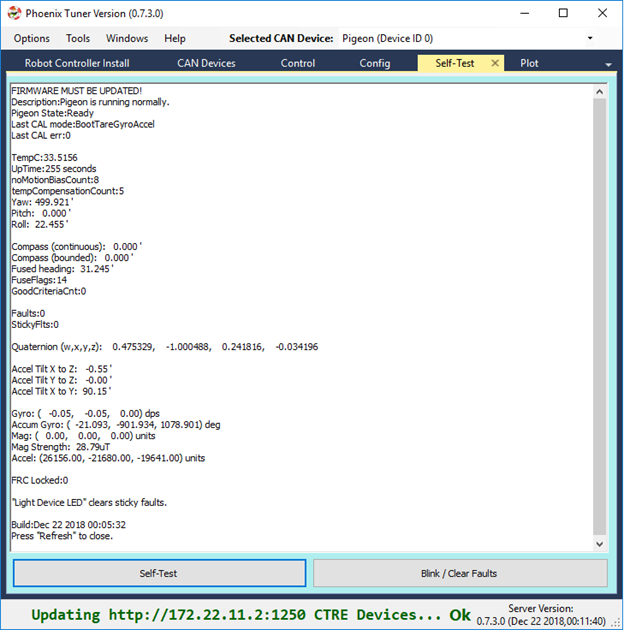

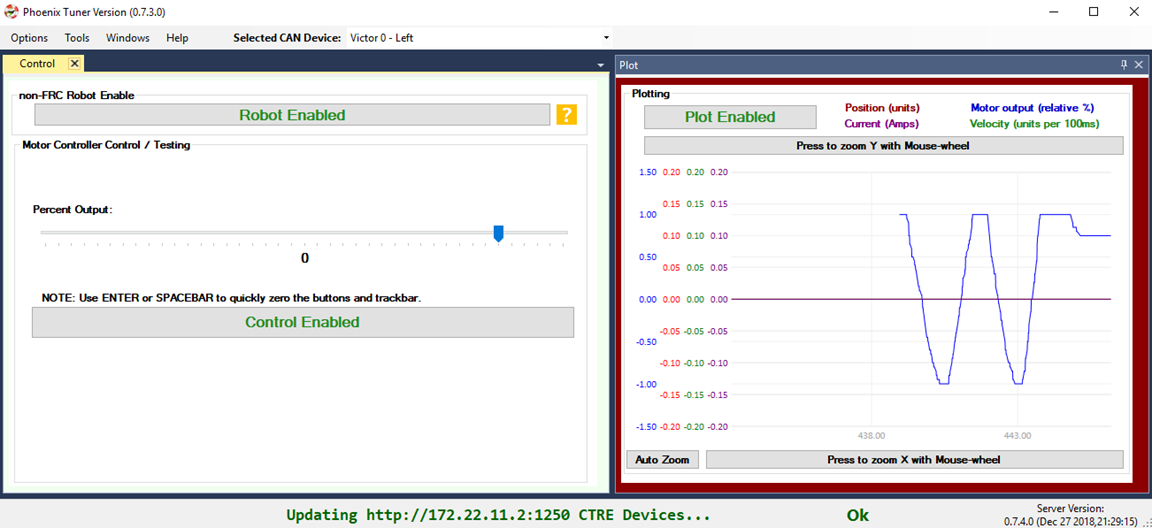

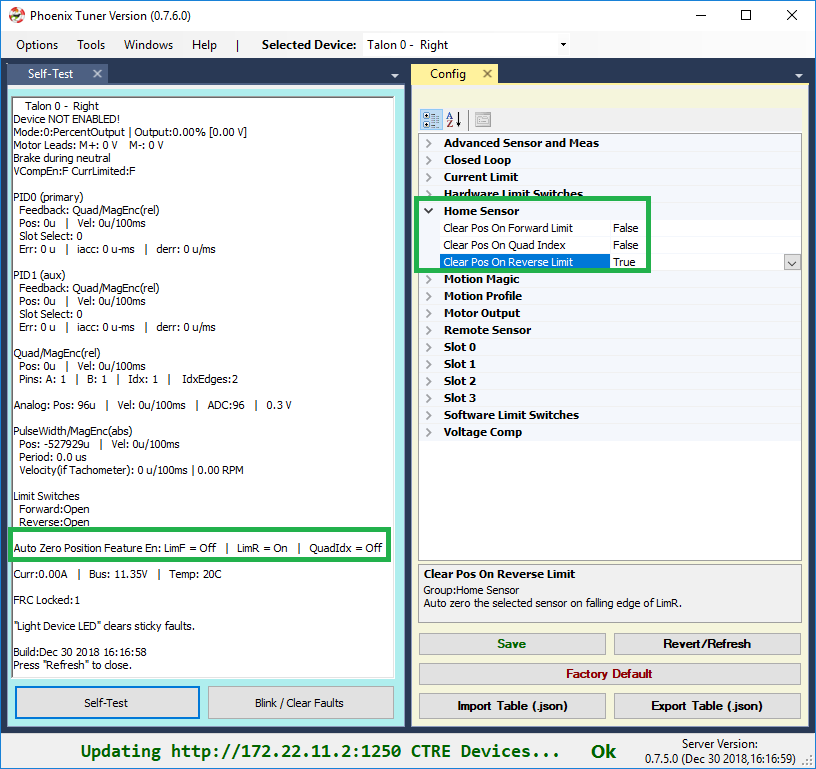

Latest Tuner and Diagnostic Server versions shown below (Tuner version in the top status bar, Server version in the bottom right - both report “1.3.0”).

The details of the update can be found in the release notes. See the sections below for more information and good luck this build season!

Omar Zrien Co-owner CTR-Electronics

New S-Curve feature¶

What is it?¶

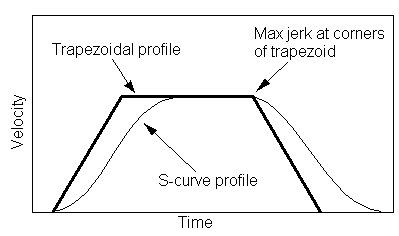

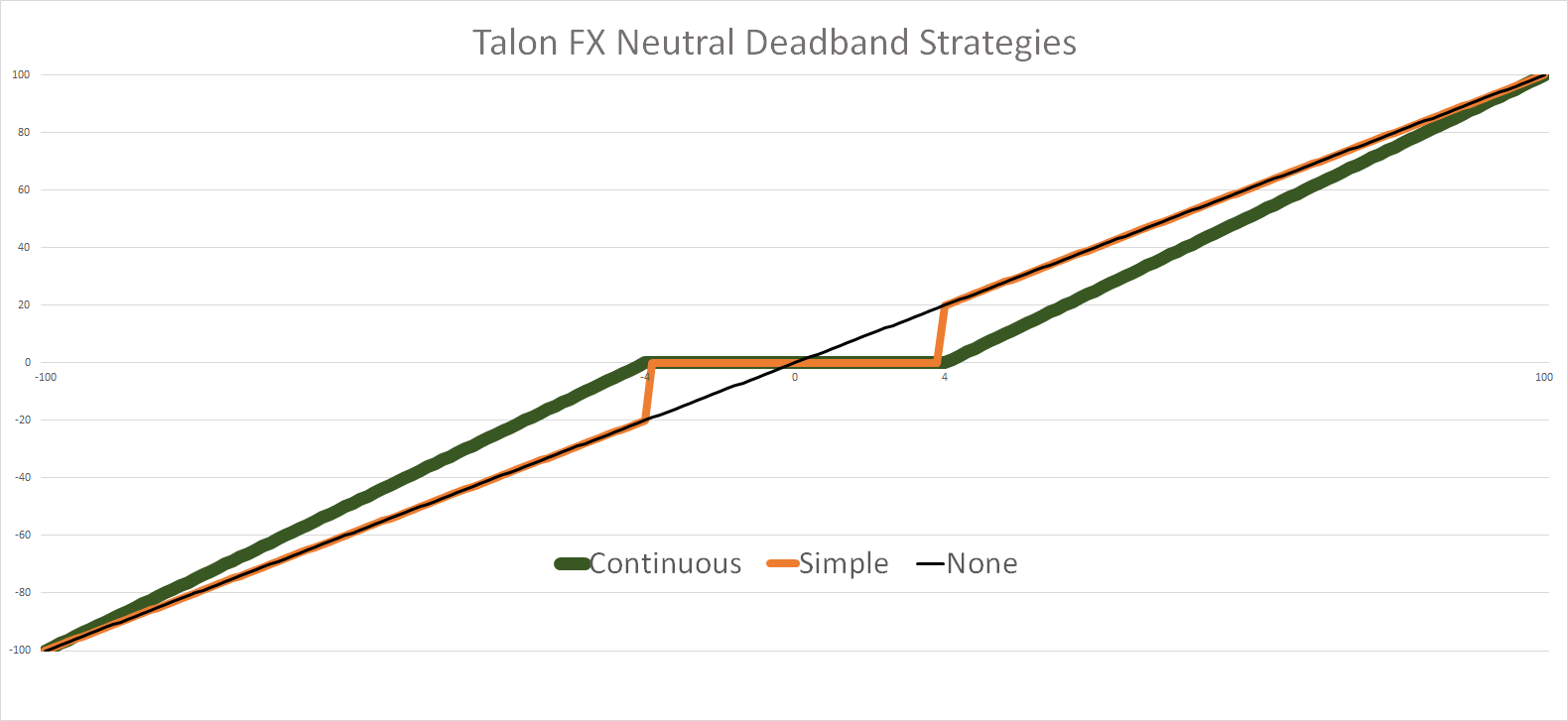

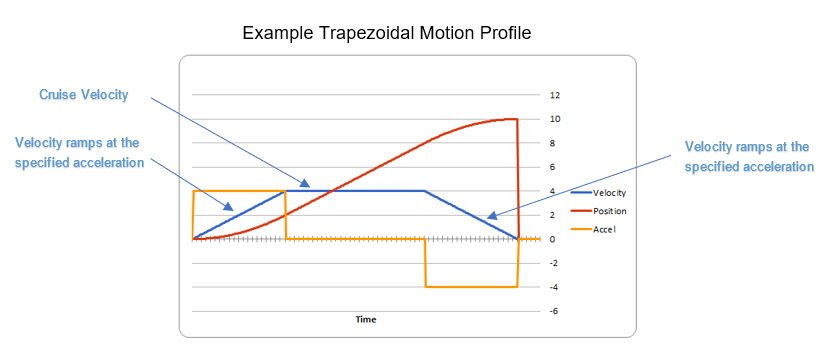

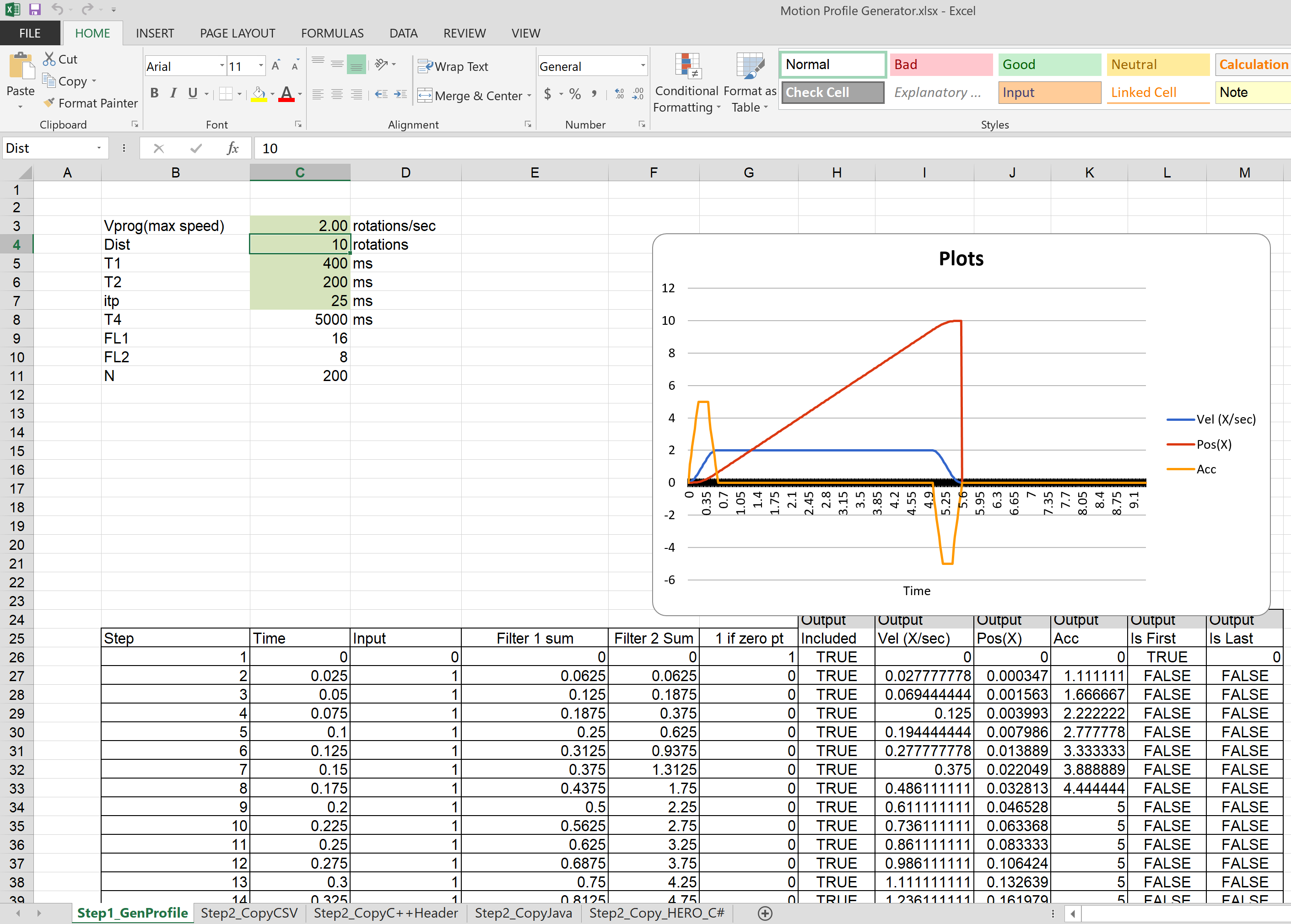

The Talon SRX and Victor SPX Motion Magic control mode has definitely had a positive impact on FRC teams since its initial release in 2017. For the first time, teams could control their velocity profiles with virtually no additional software to develop. This feature works by using a strategy called Trapezoidal Motion Profile, a technique where constant acceleration is applied when adjusting the mechanism velocity.

However, trapezoidal profiling is not commonly used in industry. Instead, true motion profilers (CNC equipment for example) use S-Curve profiling. This means that the sharp “corner” points typical of the simpler trapezoidal method are smoothed to form a continuous curve.

Note

Image source: http://www.ni.com/product-documentation/4824/en/

Due to the successful and widespread use of this control mode, we’ve enhanced it to allow for true S-Curve profiling.

Why use it?¶

Smoothing the profile generally leads to reduced oscillation in the movement caused by the “jerk” points that occur when the target velocity changes abruptly. This also means a more deliberate and reproducible maneuver, which is important in FRC.

As more teams become familiar with profiling techniques, classic trapezoidal profile may not be good enough for the future challenges team face.

How to use it?¶

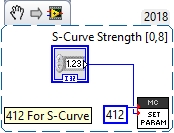

C++ and Java teams will now be able to use configMotionSCurveStrength() to select how much smoothing to apply. This setting is available in the C++/Java API, as well as latest Tuner (config tab).

There are nine levels (0 through 8), where 0 represents no smoothing (same as classic trapezoidal profiling) and 8 represents max smoothing.

This setting also defaults to 0 to ensure a “smooth” transition when migrating from the older Phoenix releases.

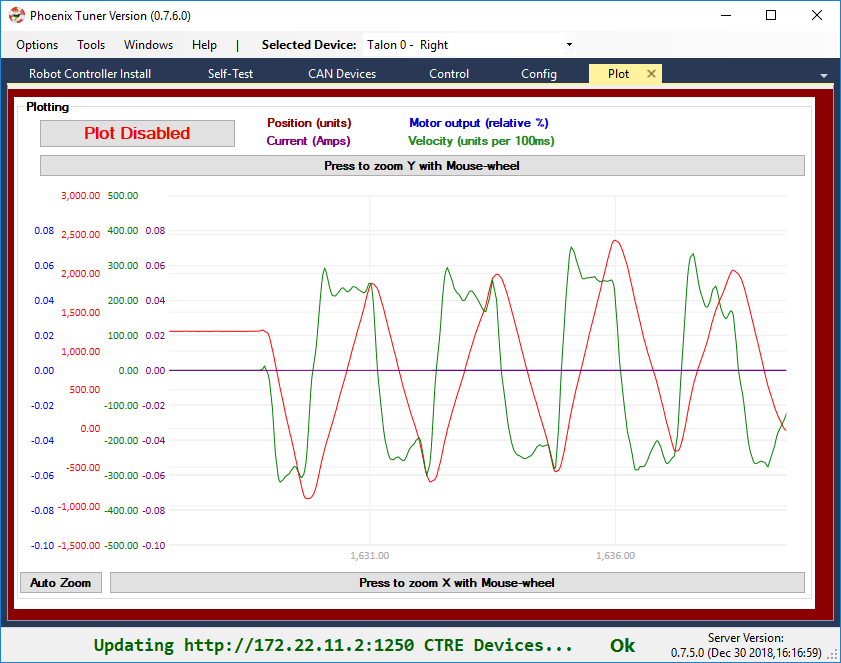

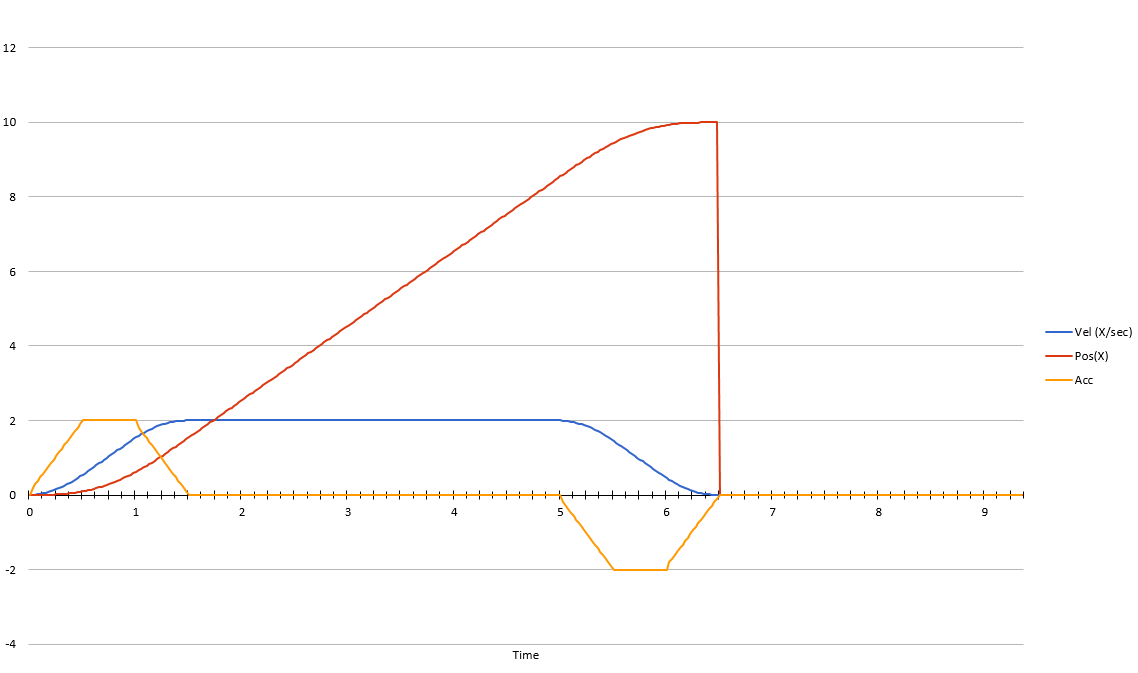

New Tuner Plotter¶

Given the enhancement to Talon/Victor profiling, we also added the ability to plot the Motion Magic / Motion Profile target position and velocity. This will allow teams to learn about and tweak their profiles, as well as experiment with the new S-Curve feature.

Note

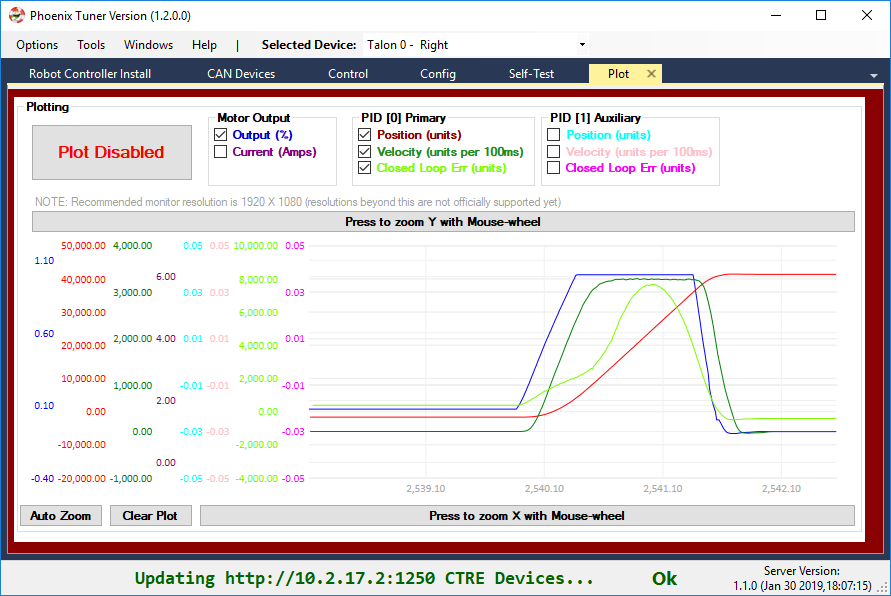

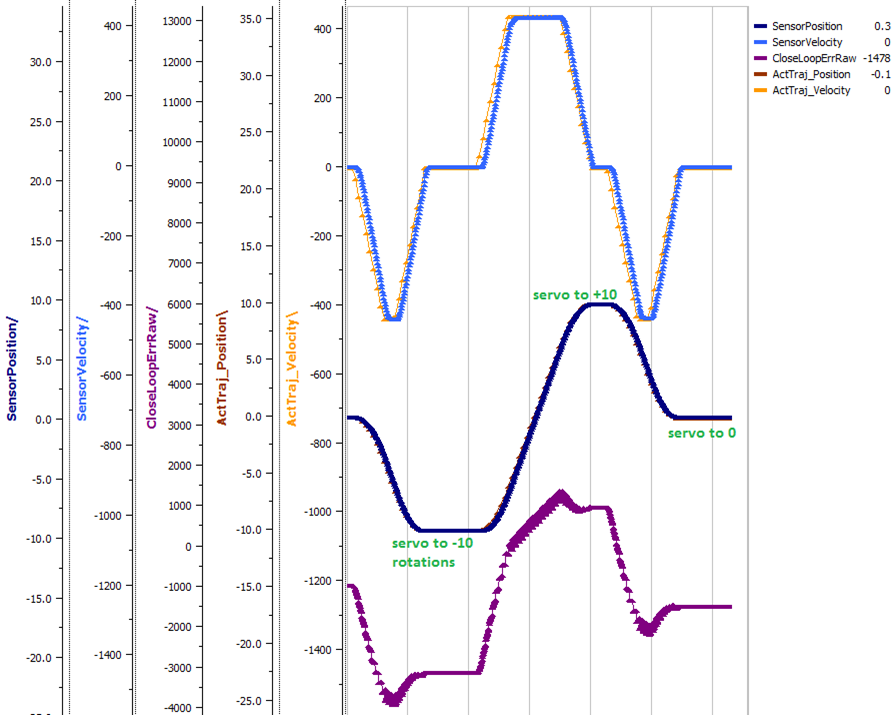

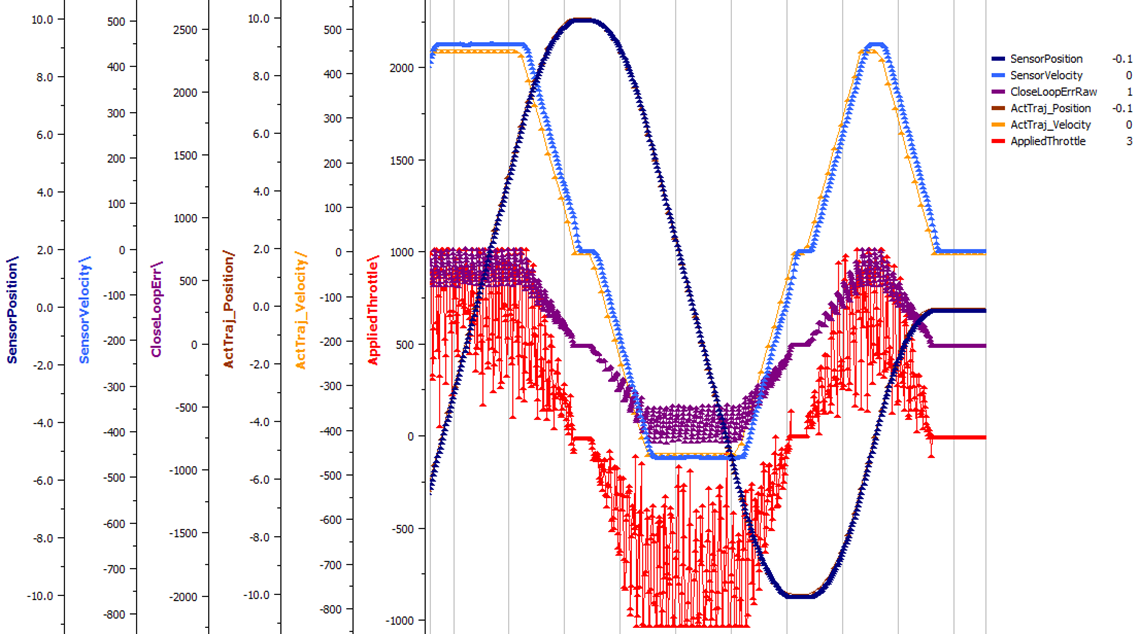

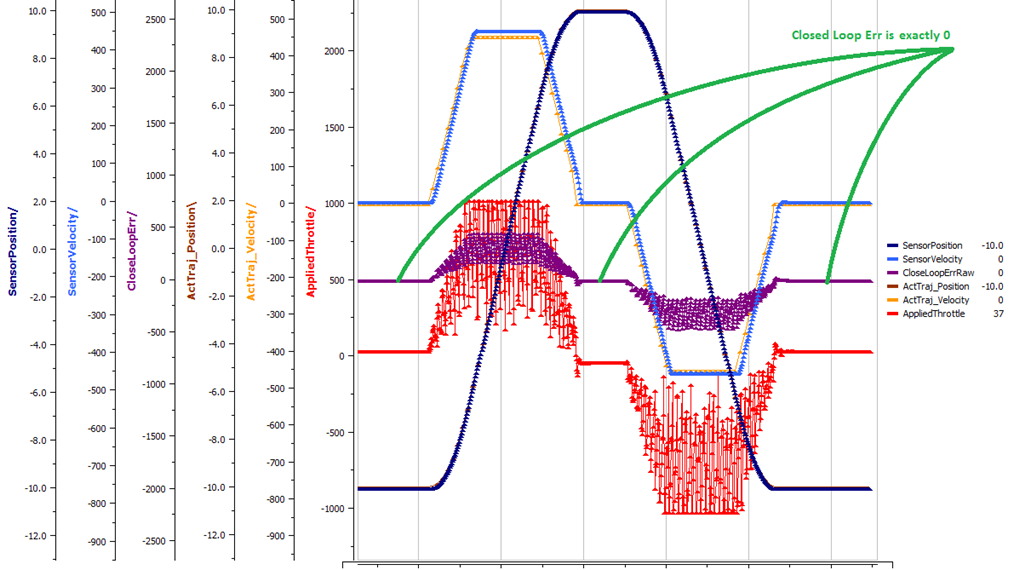

The capture below shows a “smoothed” MotionMagic velocity curve.

Note

The target velocity and position is also updated when using Motion Profile (streaming).

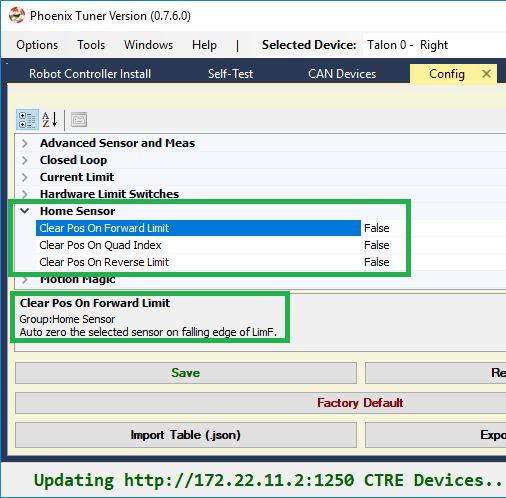

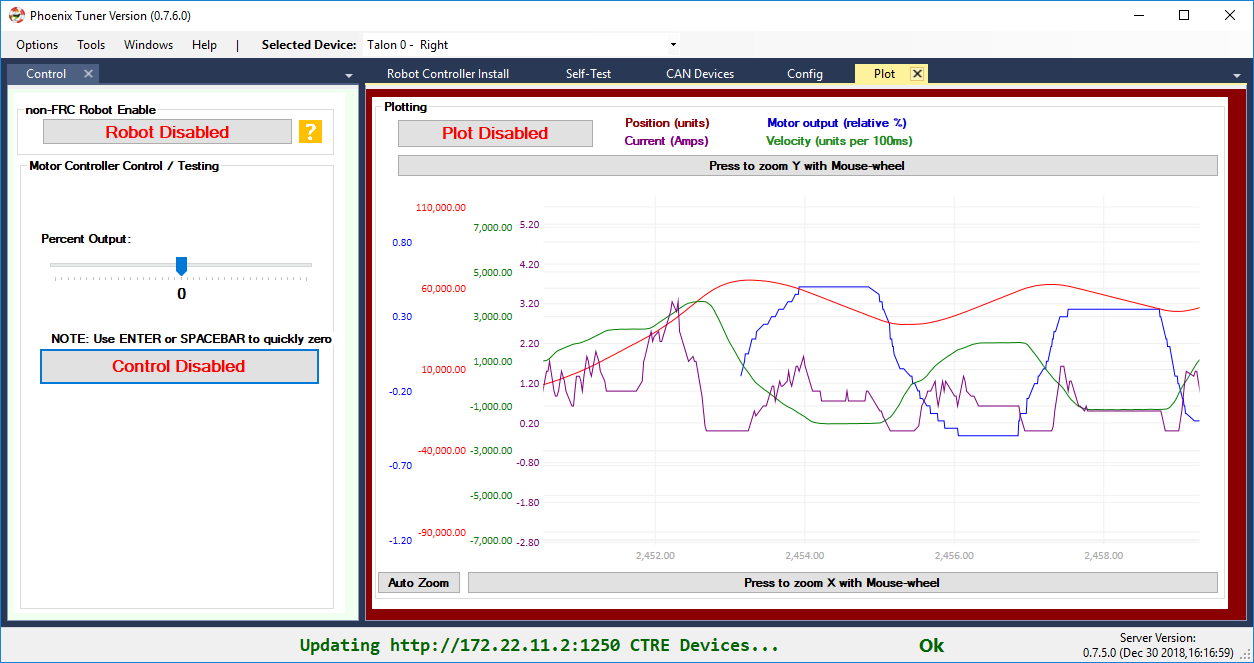

New Tuner Control¶

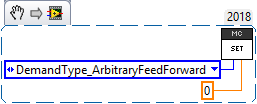

The Tuner control tab now provides the means of testing:

Percent Output

Position Closed-Loop

Velocity Closed-Loop

Motion Magic Closed-Loop

Current (draw) Closed-Loop

The graphical interface has been enhanced a bit to cover the various combinations of control strategies. For teams who leverage advanced features (such as arbitrary feed-forward or auxiliary PID1), uncheck the “Simple View” checkbox to get all the bells and whistles.

How To download¶

Windows users can download the v5.14 Installer, which provides all three components.

Alternatively, users can download the individual components:

Release page on GitHub: https://github.com/CrossTheRoadElec/Phoenix-Releases/releases

Firmware can be downloaded from the product pages on http://oldsite.ctr-electronics.com/

Additionally teams can pull the latest Phoenix API via the online method through VS Code, or via the non-Windows zip.

Download instructions can be found here.

Note

The online method refers to the “Check for updates (online)” feature. However this is not recommended as this requires a live Internet connection to use your FRC project.

BLOG: FRC 2019 Week 4¶

Hello FRC Community!

This week we are releasing our first comprehensive update for the 2019 season. Our test plan for this release was vigorous and took longer than we expected to complete, but we are satisfied with the results.

In this release the following components were updated:

New Tuner v1.2 (with Diagnostic Server v1.1)

New Phoenix API v15.3

New Firmware for Talon SRX (4.15), Victor SPX (4.15) and Pigeon IMU (4.13).

A breakdown of the changes are below, but due to the variety of improvements and how these components interact, we strongly recommend collectively updating all three components before Stop Build Day.

How To download¶

Windows users can download the v5.13 Installer, which provides all three components.

Alternatively, users can download the individual components:

Release page on GitHub: https://github.com/CrossTheRoadElec/Phoenix-Releases/releases

Firmware can be downloaded from the product pages on http://oldsite.ctr-electronics.com/

Additionally teams can pull the latest Phoenix API via the online method through VS Code, or via the non-Windows zip.

Download instructions can be found here https://phoenix-documentation.readthedocs.io/en/latest/ch05_PrepWorkstation.html#what-to-download-and-why

Note

The online method refers to the “Check for updates (online)” feature. However this is not recommended as this requires a live Internet connection to use your FRC project.

See the sections below for more information and good luck this build season!

Omar Zrien Co-owner CTR-Electronics

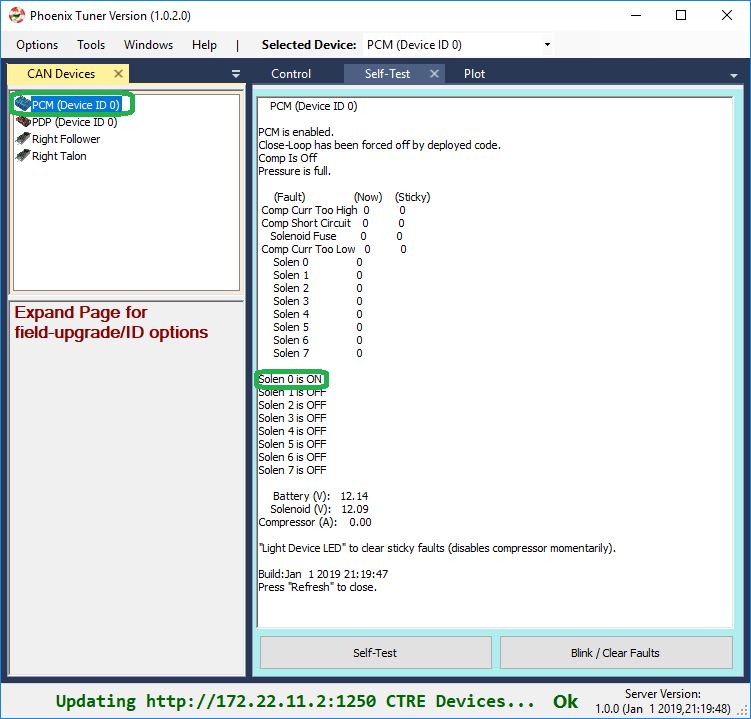

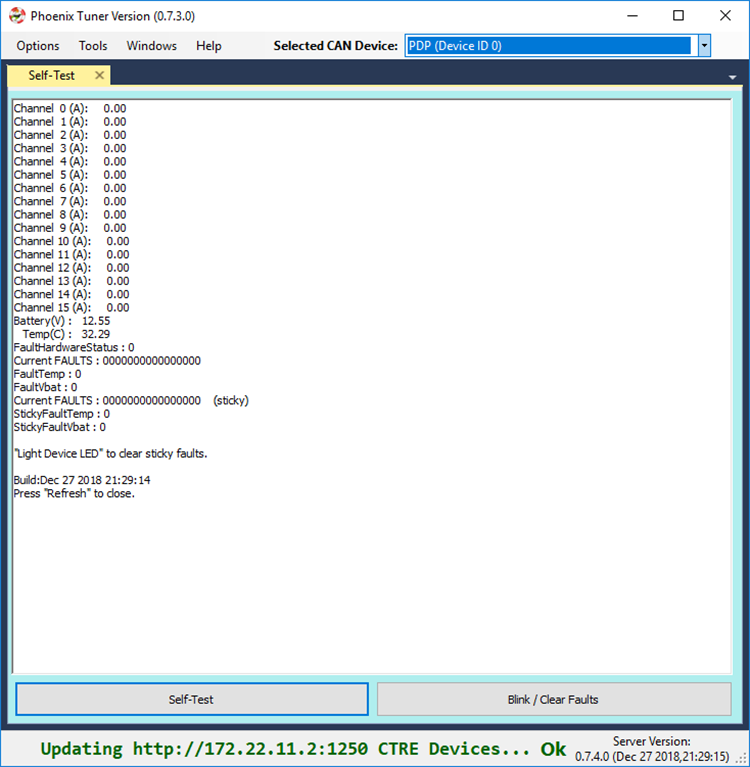

New Tuner v1.2 (with Diagnostic Server v1.1)¶

Comms Improvements¶

The biggest update to the Phoenix Tuner/Diagnostic Server package is updating the communication method to use the latest Windows web-request API. This appears to have solved the remaining customer reports where the browser responds correctly to Diagnostic Server, but Tuner does not.

Memory and performance improvements were also made to improve the runtime behavior when leaving the software connected for extended periods of time.

If you experienced any communication issues with the Kickoff release of Tuner, we strongly recommend switching to the latest Tuner and installing the latest Diagnostics Server (Robot Controller Install tab).

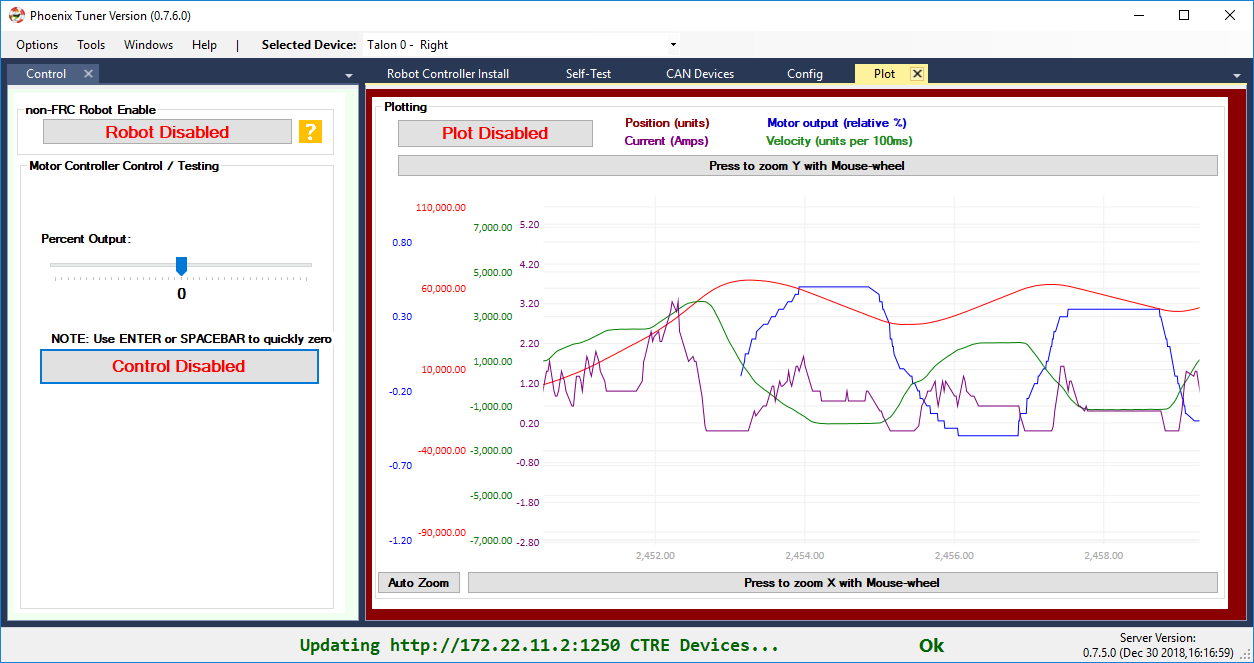

Plotter Improvements¶

Some teams are beginning to move into the “tuning” phase of their mechanisms, so we added a few more channels to the plotter.

Phoenix Libraries cleared on roboRIO reboot¶

We received a couple reports where the roboRIO appears to be losing Phoenix libraries after a power cycle. The root-cause was determined to be teams accidently using HERO LifeBoat to install 2018 libraries in a location that prevents the 2019 libraries from loading correctly. Details on this can be found at https://github.com/CrossTheRoadElec/Phoenix-Releases/issues/1

To solve this completely we made two changes:

Latest Phoenix Tuner will find and delete the erroneously placed 2018 library files.

Latest HERO LifeBoat will not install libraries into a roboRIO.

If this applies to your robot, we recommend downloading latest Tuner (via Windows Installer or via GitHub releases) and perform a fresh “Robot Controller Install” to ensure no loss of functionality after RIO reboot.

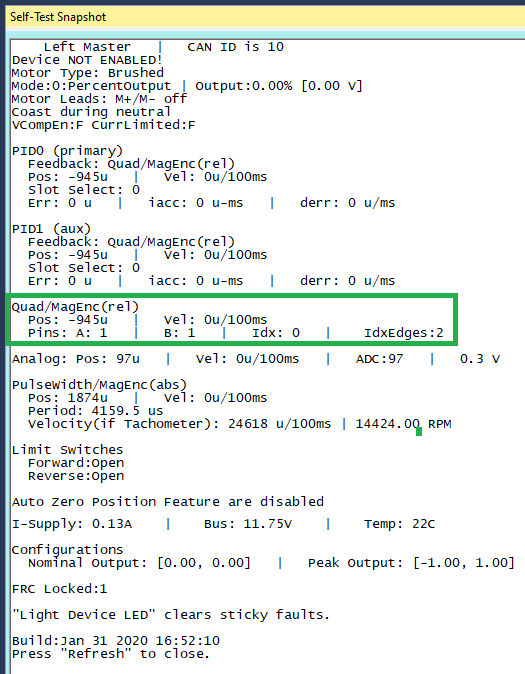

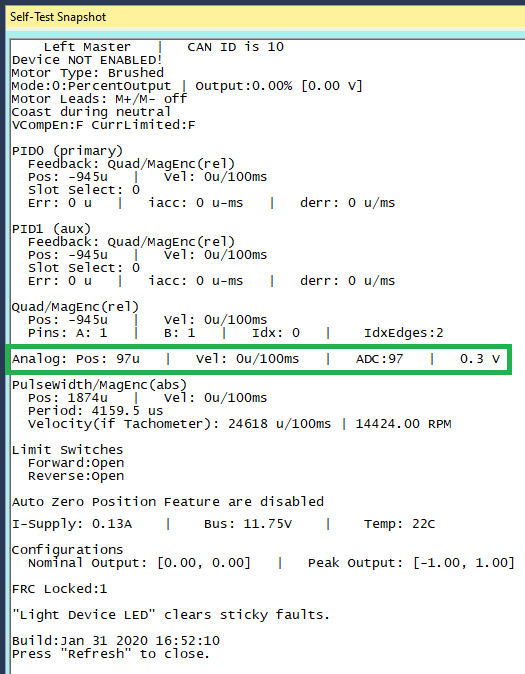

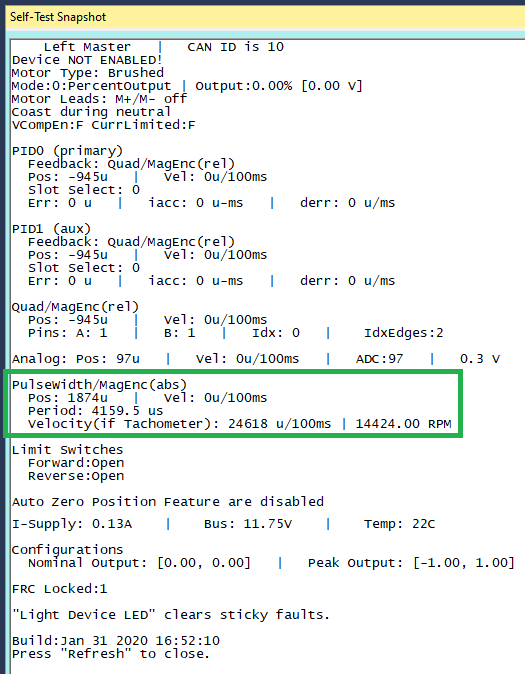

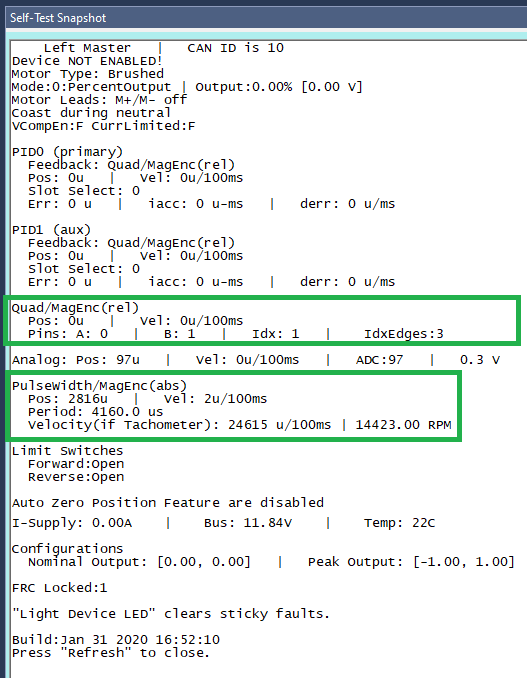

Misc Updates¶

We’ve also made several minor corrections to the Self-test Snapshot results, and compatibility adjustments to match latest firmware. The details can be found in the release notes.

New Phoenix API v15.3¶

Desktop Simulation - Our first steps¶

Teams using VS Code may have noticed a checkbox in the “Create New Project” prompt for “Desktop Support”. When checked, the newly created project is setup to perform desktop compilation in addition to compiling for the roboRIO. This can provide the means of testing newly written code when you are away from the roboRIO.

In the previous 2019 release of Phoenix, the desktop libraries required for this feature were not packaged. But that has changed - starting with v5.13, you can now set this checkbox, thereby enabling the desktop builds to compile on your native machine. This means your roboRIO project that links Phoenix will now compile on Windows/Linux desktop.

Note

This may slow the build time of your source due to the additional compile tasks.

Although the project will compile, you will notice the typical Driver Station errors when communicating with CTRE Devices that are not present on the CAN bus. This is why we consider this our “first step” in simulation. Future releases will include more comprehensive support, with the ultimate goal of full-simulation of our CAN devices.

Jetson TX and Raspberry Pi¶

The classifiers for our armhf and aarch64 builds have been modified to explicitly name the Jetson TX2 and Raspbian toolchain. This better communicates the intended target platforms of these libraries, and aligns the Raspbian binary artifacts with WPILIB’s naming scheme.

Pigeon Pitch/Roll¶

A couple teams reported that the API to poll Pitch and Roll were not correct if the angle is steep enough. This has also been solved in this release.

New Firmware - Talon SRX (4.15), Victor SPX (4.15) and Pigeon IMU (4.13)¶

Pigeon IMU (4.13)¶

This hot-fix was released over two weeks ago to solve an issue for teams using the remote-sensor/Arc features of the Talon SRX.

https://github.com/CrossTheRoadElec/Phoenix-Releases/releases/tag/Pigeon_IMU_v4.13

Since this is the first installer since the hot-fix, this CRF has been included.

Talon SRX / Victor SPX Firmware (4.15)¶

A critical fix has been applied to the Talon SRX and Victor SPX firmware for those of you using the firmware closed-loop features. We’ve identified a circumstance where measurement noise can occur in the sensor velocity and closed-loop derivative error, when motor output is less-than-full, and the current-draw measurement is nonzero and changing.

This was first discovered and reproduced by FRC Team 2767 Strike Force. If that name sounds familiar, you’ve probably watched an FRC World Championship, or two.

Thanks to the feedback from 2767, we’ve solved the issue with several performance improving fixes. The issue was root-caused to be an inefficiency in the current-draw calculation, which has been addressed in 4.15. Note that the current-measurement in 4.15 may report slightly different values when compared to previous firmware (within 0.100A) due to rounding changes.

Because measurement noise can be very difficult to diagnose, we strongly recommend teams using the closed-loop features of Talon to update. If you are using the closed-loop features successfully, you may find that updating will improve your tuning experiences (gains seem to be easier to find).

Additional firmware updates¶

The additional firmware changes are also mentioned in the release notes.

BLOG: FRC 2019 Week 1¶

Hello FRC Community,

It’s the end of “week 1” of the build season, and a good time for an update from CTRE.

C++/Java teams appear to generally be successful becoming familiar with this year’s new software collection (VS Code + Phoenix + Tuner). If your team has not updated yet, we recommend starting with WPI Screensteps, then running through Phoenix Framework Documentation for CTRE devices.

LabVIEW teams appear to be up and running as well with our kickoff software library. We’ve encountered a single report of an install related issue, which has been reproduced and fixed. As a reminder to teams, please use Tuner to install the Phoenix library into your roboRIO, and not last year’s HERO LifeBoat.

See the sections below for more information and good luck this build season!

Omar Zrien

Co-owner CTR-Electronics

Updated API Docs¶

This week we went through our C++/Java API filling in any missing comment block sections. The online API doc has been updated for C++ and Java. Of course if you still have questions, feel free to contact our support directly.

Remember to update the firmware!¶

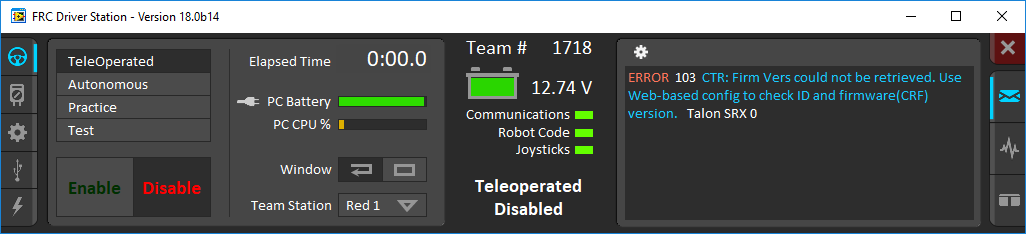

We got a few support calls/emails this week from teams reporting that their Talon SRX motor controllers would not enable as expected. Here were the root-causes we found:

Wrong firmware - Didn’t update.

Still wrong firmware, where is the web-dash? What’s Phoenix Tuner?

Didn’t set device IDs.

We are supposed to use VS Code now? When did that happen?

No we didn’t install anything called Phoenix. What’s that?

But more often than not, the root-cause was not updating to this year’s firmware (4.11). Once updated, teams were ready to rock and roll.

So as a reminder, teams should ensure that their motor controllers are up to date for proper functionality with 2019 software.

Phoenix on other platforms?¶

Some teams are already aware that Phoenix isn’t just a library targeted for the roboRIO. For those of you perusing our maven site you may have noticed several Linux binaries. These have been used for leveraging Talons/Victors/CANifiers/Pigeon on third party hardware such as:

Raspberry PI + SocketCAN interface

NVIDIA Jetson TX2 + native CAN

Even Linux Desktop with SocketCAN device plugged in.

After reviewing the FRC rules, it appears that leveraging these CAN devices from third-party CAN hardware is now officially FRC legal. This opens up an entirely new way to develop robots in FRC.

Want to update your set-points from your Raspberry PI vision system?

Want to run closed-loops in your NVIDIA Jetson?

Do you prefer a development platform/environment outside of the roboRIO control system?

For the first time ever, you can now update your control outputs outside of the roboRIO, while the roboRIO safely manages the enable/disable of your Talon SRXs and Victor SPXs.

The requirements for this are to link the appropriate Phoenix-targeted library into your application (typically Linux-amd64, Linux-armhf, Linux-aarch64), allowing you to use the same Phoenix API on your platform.

Additionally you must provide a CAN bus interface. A popular method to do this is with through SocketCAN.

And finally make sure Phoenix loads on the roboRIO, either by creating a dummy Phoenix CAN device that is not on the bus, or calling the new loadPhoenix() routine.

We have a GitHub example demonstrating this type of control on an FRC robot with a Raspberry PI + CANable(USB). Driver station is used to enable/disable the robot, and the rest is done in the Raspberry PI C++ application.

Note

Reading gamepads inputs on a raspberry pi is typically not FRC legal, but controlling the Talons from the pi now is.

Note

This applies to CAN-bus control of Talon SRX/Victor SPX, and not PWM.

Phoenix Tuner 1.0.2¶

We released a minor update to Tuner today. Tuner 1.0.2 is packaged with today’s installer (see below) but also available as a separate download…

https://github.com/CrossTheRoadElec/Phoenix-Releases/releases

Fixes:

Improved the form response to high-dpi monitors. Note that the plotter features still work best at 1920 X 1080 (otherwise Windows may auto-scale the application on plotter-enable).

Improved mDNS resolving. This improves discovery of the roboRIO when user enters team number instead of a static-IP or 172.22.11.2 (USB) host name.

Phoenix Framework 5.12.1¶

We also released a minor Phoenix update today.

https://github.com/CrossTheRoadElec/Phoenix-Releases/releases

The same API comment-block updates that were applied on our site are now in our library so that VS Code Intellisense can display more information.

Tip

C++ teams may have to invoke “./gradlew clean” and/or “WPILib C++: Refresh C++ Intellisense” for Intellisense to update.

Our maven site has also been updated with the 5.12.1 libraries.

We also added more firmware version checking (we report a DriverStation message already, but we now do it as soon as the Phoenix object is created, instead of waiting for you to call certain routines). We were motivated to do this due to the support calls we got this week mentioned earlier :)

And finally we fixed the context help for SetInverted.vi (LabVIEW), this was reported by a team.

This minor update also provides an opportunity for C++/Java teams to become familiar with the “Update” instructions for third-party libraries. Be sure to review the update instructions

Balance Bot¶

Last year during the Worlds Championships, we demoed a small 2-wheeled balance bot using our HERO control system. No, I don’t expect any competition robots to employ the same drive train :)

But during the off-season, we redesigned it to be easier to 3D print, assemble, and support. Earlier this week we were asked about the demo, only to realize we never posted the files!

The CAD and source is now available on GitHub.

BLOG: FRC 2019 Kickoff¶

Once again it is time to kick off a new FRC season!

The Phoenix installer and non-Windows binary kit is now available.

You can also find the latest firmware CRFs at each product page (the installer also installs them).

The new features included in this season’s release are listed below. What’s great about this list is that every single feature was a request from an FRC student or mentor. Also this year’s API release is almost entirely backwards compatible.

New features below¶

Motor controller followers can use SetInverted(enum) to match or oppose master motor controller. SetInverted(bool) still exists and works exactly the same as last season.

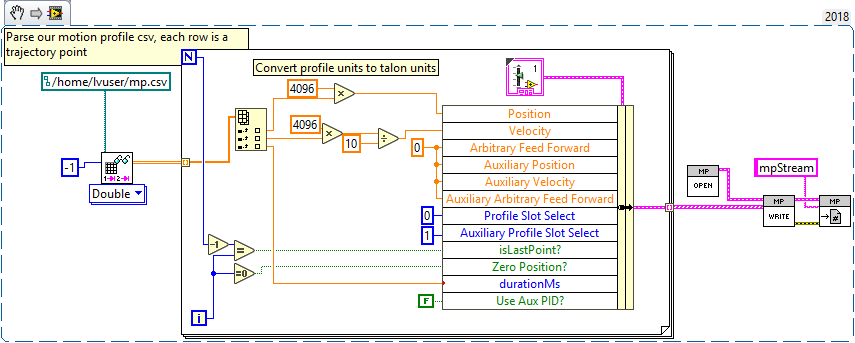

Motion Profile and Motion Profile Arc have an explicit feedforward term (allows for kS, kV, kA, etc..) for both primary and aux PIDs.

Motion Profile (and Arc) use a linear interpolator to adjust the targets every 1ms. This means you can send less points, reducing CAN bandwidth, but still have resolute control.

Motion Profile API has a simpler mode where you can simply call Start/IsFinished. Legacy API still exists and is supported.

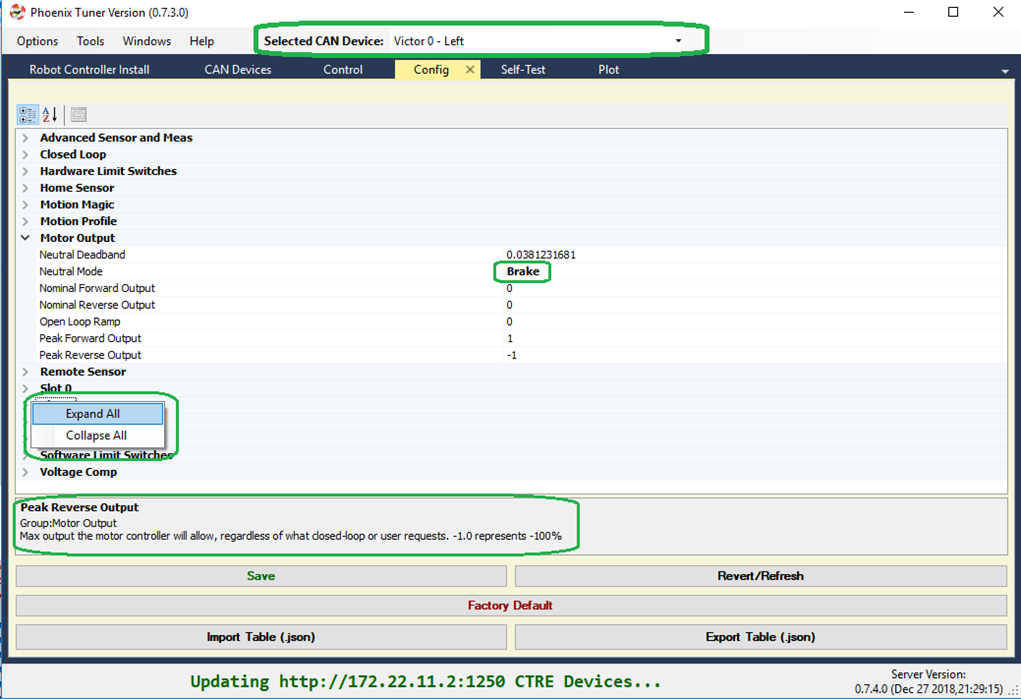

Phoenix Tuner and Phoenix Diagnostics Server replaces the silverlight based diagnostics from past seasons.

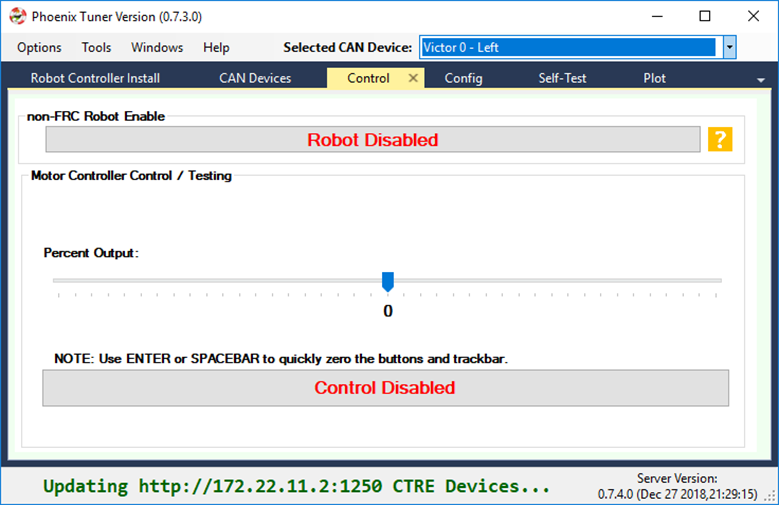

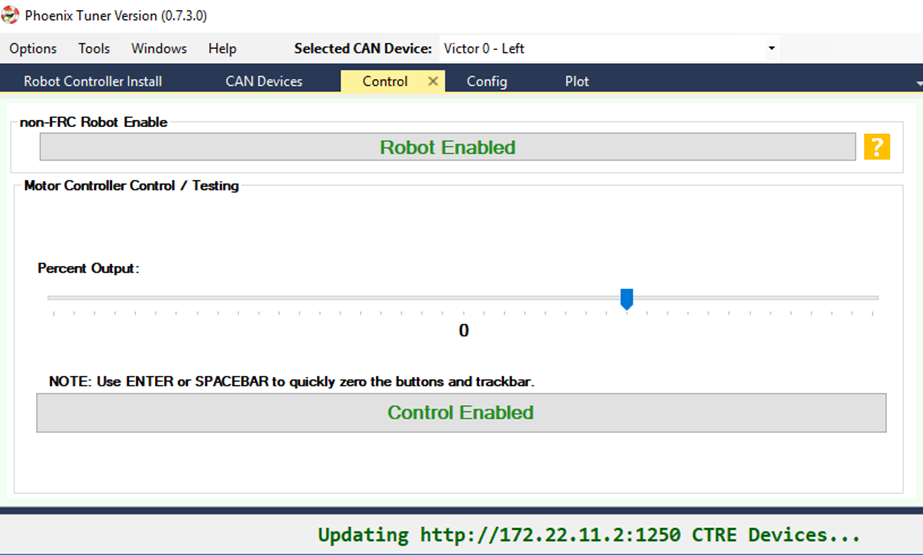

Phoenix Tuner provides the means of controlling Talons for simple testing.

Phoenix Tuner includes a plotter.

Phoenix Tuner provides import and export of all config settings.

Phoenix Tuner can be used to factory default config settings (as well as API).

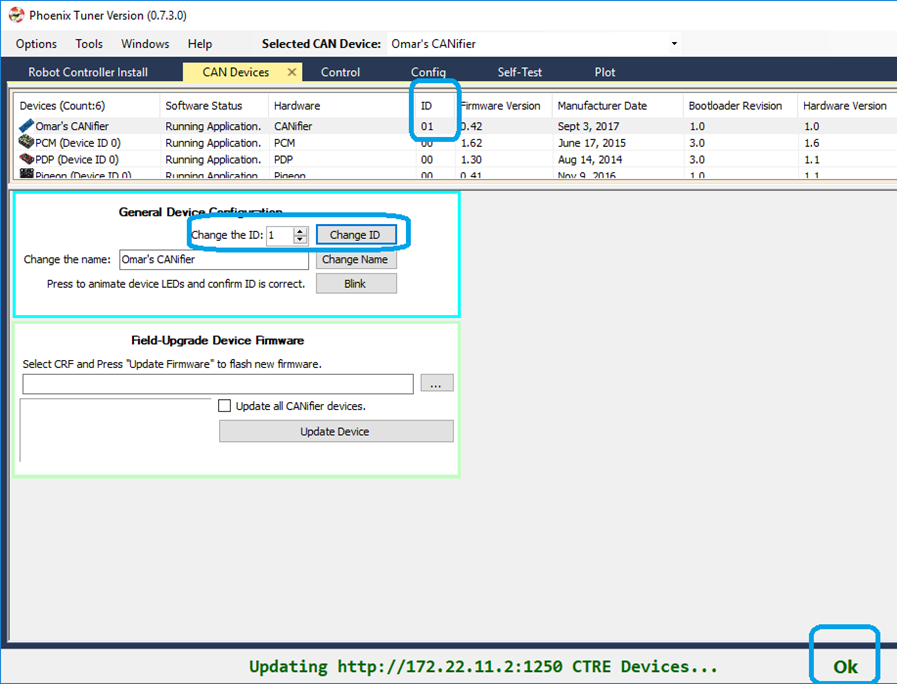

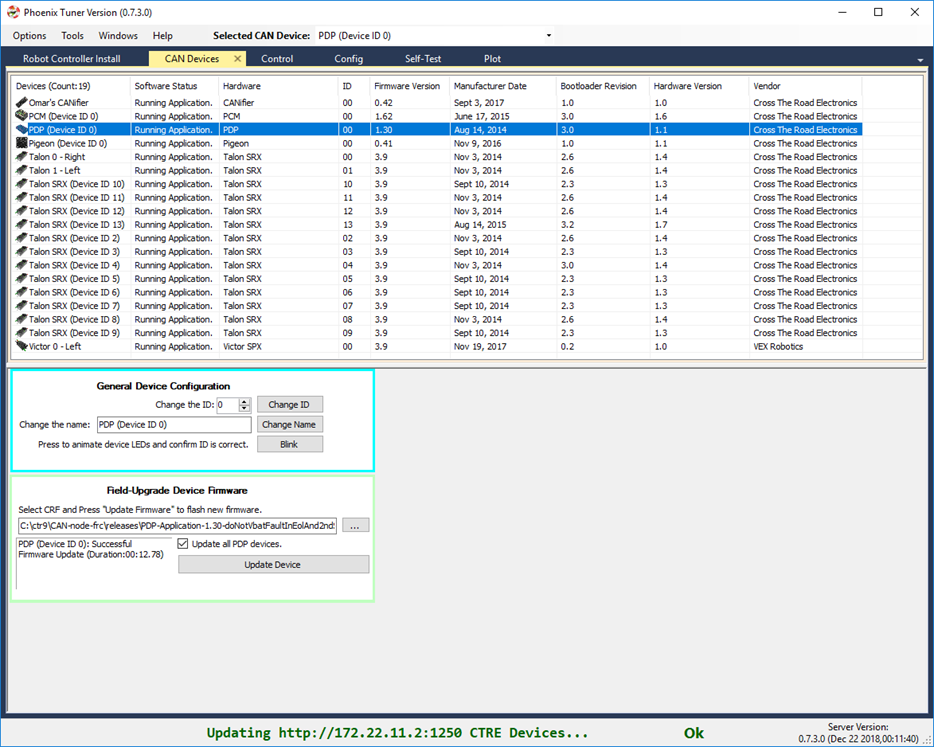

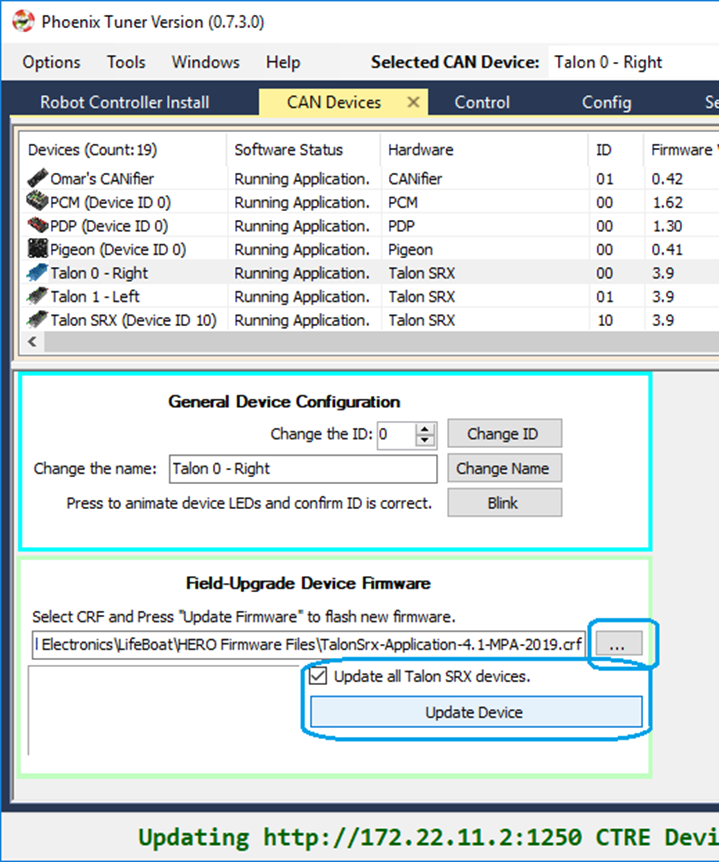

Phoenix Tuner can field-upgrade all same-model devices with one click.

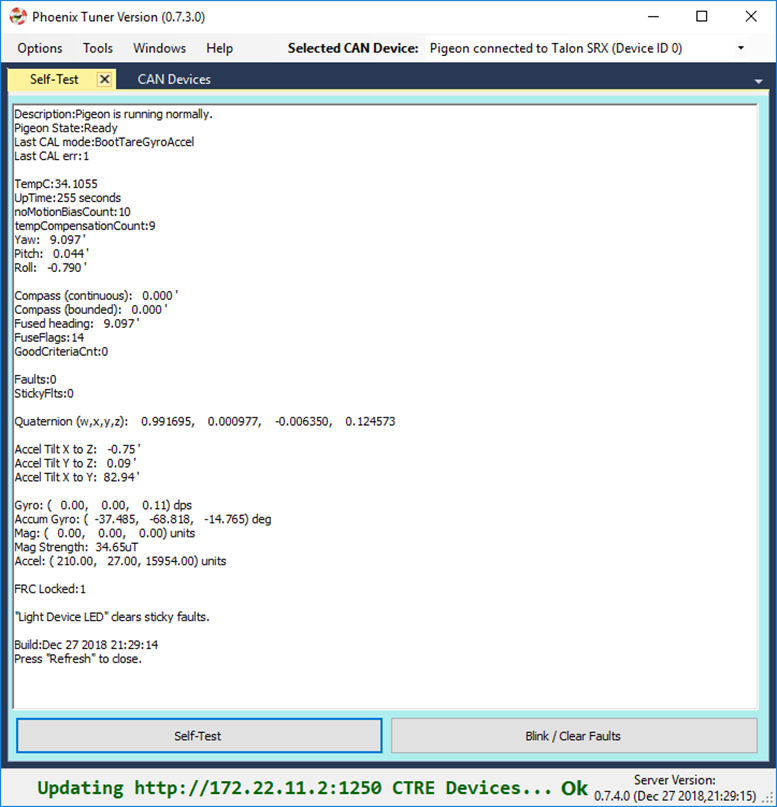

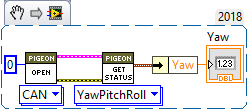

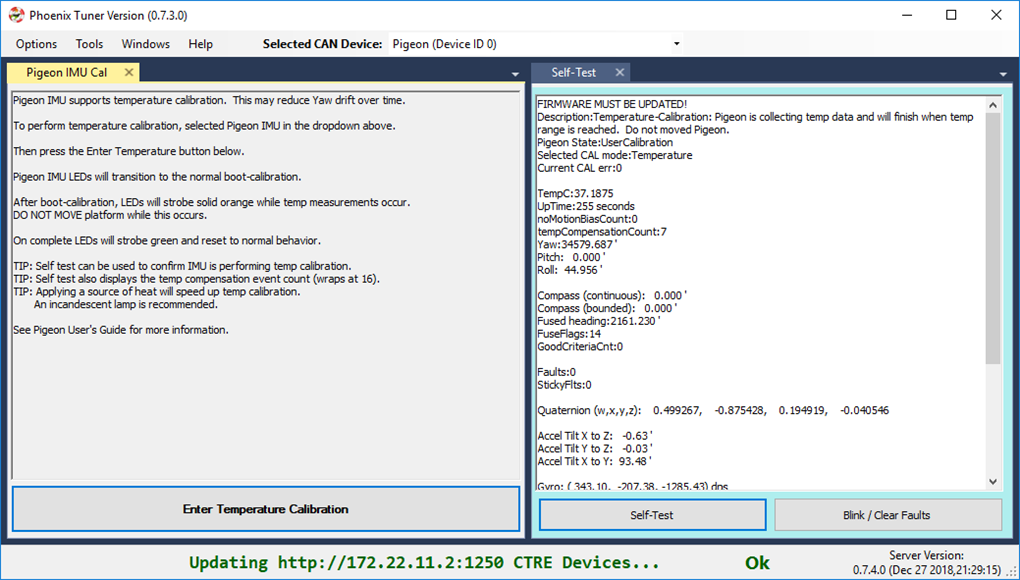

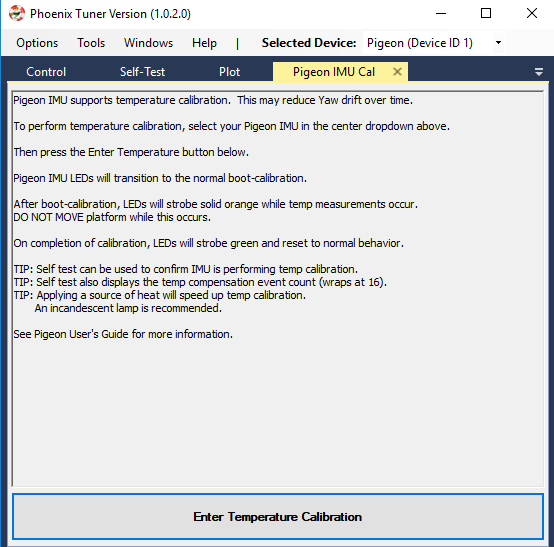

Phoenix Tuner can be used to perform Pigeon IMU temperature calibration.

New config routines to simplify management of persistent settings: configFactoryDefault and configAllSettings

Compatibility with WPI distributed Visual Studio Code interface and GradleRIO build system.

Maven hosted API provides an alternative to using the Phoenix installer to get API binaries (however the offline install is highly recommended).

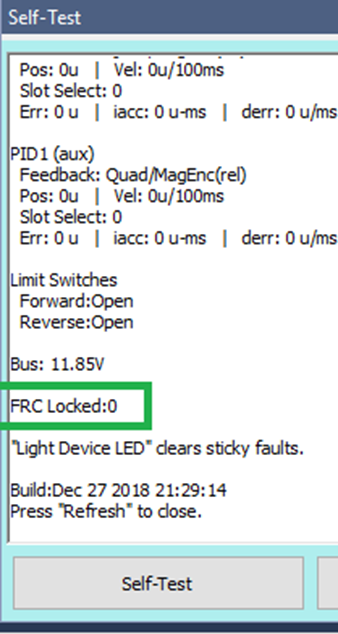

No more FRC versus nonFRC firmware, see “FRC Lock” features for explanation.

Phoenix C++ API is portable to RaspPI, Linux-Desktop, NVIDIA Jetson TX2, etc.

Performance improvements of general status CAN get routines (get routines take far less time to execute than previous seasons).

Talon SRX: Maximum reportable velocity increased. New maximum RPM is 38400 RPM (@ 4096 untis per rotation).

C++/Java: Added default parameter values for pidIdx, slotIdx, and timeoutMs where appropriate.

Note

Installing Phoenix on another Linux device and controlling Talon SRX / Victor SPXs may or may not be FRC legal depending on 2019 rules.

Fixes¶

Current Limit Errata fixed from last year on Talon SRX.

SetYaw fixed from last year to be in degrees on Pigeon IMU.

Back-breaking API changes¶

If using Motion Profile Arc, be sure to set the bAuxPID flag to true in the trajectory points. This member variable did not exist before.

Motion Profile Trajectory point duration is now integer (milliseconds) with [0,127] ms range.

MotionMagicArc enum removed from LabVIEW. This enum was never used. Arc’ing with Motion Magic is accomplished with the four-parameter set() and MotionMagic enum.

Good luck this build season! - Omar Zrien

Phoenix Software Reference Manual¶

This is the latest documentation for CTR-Electronics Phoenix software framework. This includes:

Class library for Talon SRX, Victor SPX, CANifier and Pigeon IMU (C++/Java/LabVIEW for FRC, C# for HERO).

Phoenix Tuner GUI - provides configuration options, diagnostics, control and plotting.

Phoenix Diagnostic Server - install on to RIO for Tuner, and to perform HTTP API requests for diagnostic information.

Be sure to follow the following instructions in order to ensure success in developing your robot platform.

Primer: CTRE CAN Devices¶

CTR-Electronics has designed many of the available CAN bus devices for FRC-style robotics. This includes:

Talon FX, Talon SRX, and Victor SPX motor controllers (PWM and CAN)

CANCoder

Pigeon IMU

CANifier

Pneumatics Control Mode (PCM)

Power Distribution Panel (PDP)

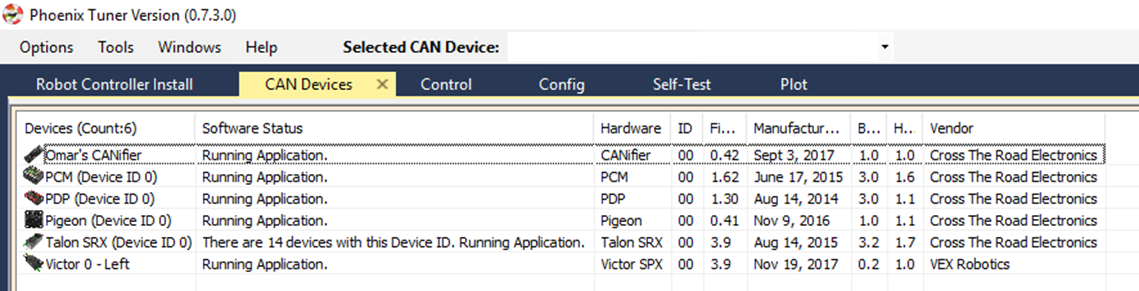

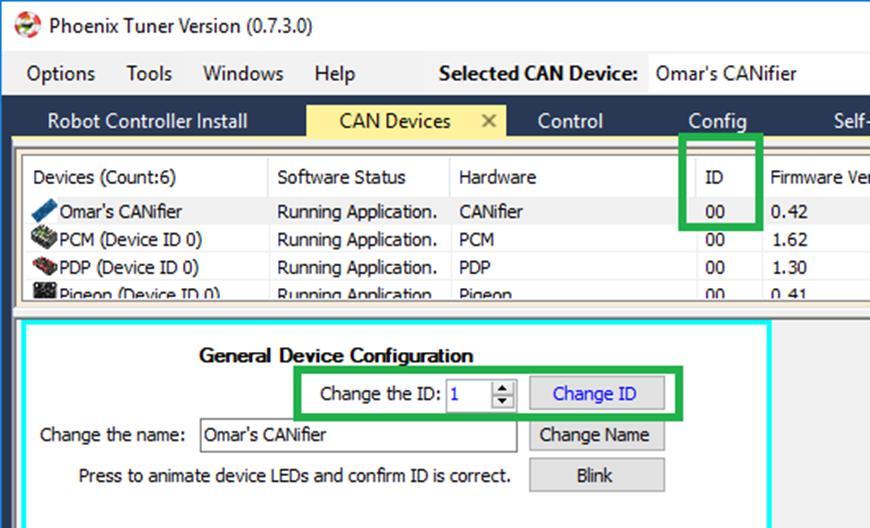

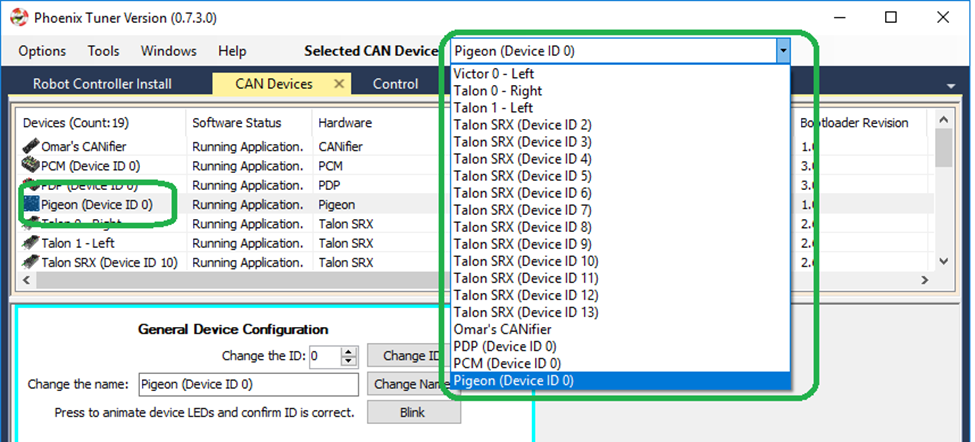

These devices have similar functional requirements, specifically every device of a given model group requires a unique device ID for typical FRC use (settings, control and status). The device ID is usually expressed as a number between ‘0’ and ‘62’, allowing use for up to 63 Talon SRXs, 63 Victors, 63 PDPs, etc. at once. This range does not intercept with device IDs of other CAN device types. For example, there is no harm in having a Pneumatics Control Module (PCM) and a Talon SRX both with device ID ‘0’. However, having two Talon SRXs with device ID ‘0’ will be problematic.

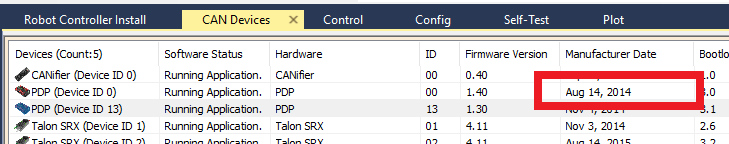

These devices are field upgradable, and the firmware shipped with your devices will predate the “latest and greatest” tested firmware intended for use with the latest API release. Firmware update can be done easily using Phoenix Tuner.

The Talon FX/SRX and Victor SPX provide two pairs of twisted CANH (yellow) and CANL (green) allowing for daisy chaining. Other devices such as the PDP and PCM have Weidmuller connectors that accept twisted pair cabling. Often you will be able to use your Talons and Victors to connect together your PCM and PDP to each other.

The CAN termination resistors are built into the FRC robot controller (roboRIO) and in the Power Distribution Panel (PDP) assuming the PDP’s termination jumper is in the ON position.

More information on wiring and hardware requirements can be found in the user manual of each device type.

Primer: What is Phoenix Software¶

Phoenix is a package that targets LabVIEW, C++, and Java for the FRC Robotics Controller platform, i.e. the NI roboRIO robot controller.

It includes the Application Programming Interface (API), which are the functions you call to manipulate the CTRE CAN bus devices: Talon FX, Talon SRX, Victor SPX, CANCoder, CANifier, and Pigeon IMU.

Note

PCM and PDP API are built into the core WPI distribution.

The C++ and Java APIs are very similar, typically only differing on the function name case (configAllSettings in Java versus ConfigAllSettings in C++). Because Java is more widely used in FRC than C++, this document will reference the Java routine names. C++ users should take note that the leading character of every function is UPPERCASE in C++.

Additionally, Phoenix shared libraries are also targeted for C++ on Linux (amd64, armhf, aarch64) and typically available on our maven repository. The example support libraries use socket-can for CANBus access, however custom drivers can be provided by the end user for alternative CANBus solutions (NVIDIA TX2 native CAN bus for example).

Phoenix also includes a NETMF (C#) class library for the non-FRC HERO Robot Controller. This can replace the roboRIO in use cases that don’t require the full features of the FRC control system, and are not in use during competition.

Note

With Phoenix framework, teams can control/leverage Talons, Victors, Pigeons, CANCoders, CANifiers outside of the roboRIO (e.g. Rasp-Pi or Jetson TX2), and use the roboRIO/DriverStation to safely enable/disable the actuators.

Note

Leveraging CTRE CAN devices from third-party CAN hardware was officially made FRC legal for the 2019 season.

There are tons of examples in all languages at CTRE’s GitHub account:

https://github.com/CrossTheRoadElec/Phoenix-Examples-Languages

https://github.com/CrossTheRoadElec/Phoenix-Examples-LabVIEW

Entire GitHub organization: https://github.com/CrossTheRoadElec/

Phoenix-Examples-Languages and Phoenix-Examples-LabVIEW are specifically tested on the FRC RoboRIO control system.

Phoenix-Linux-SocketCAN-Example demonstrates control of Talons from a Raspberry Pi. https://github.com/CrossTheRoadElec/Phoenix-Linux-SocketCAN-Example

What is Phoenix Tuner?¶

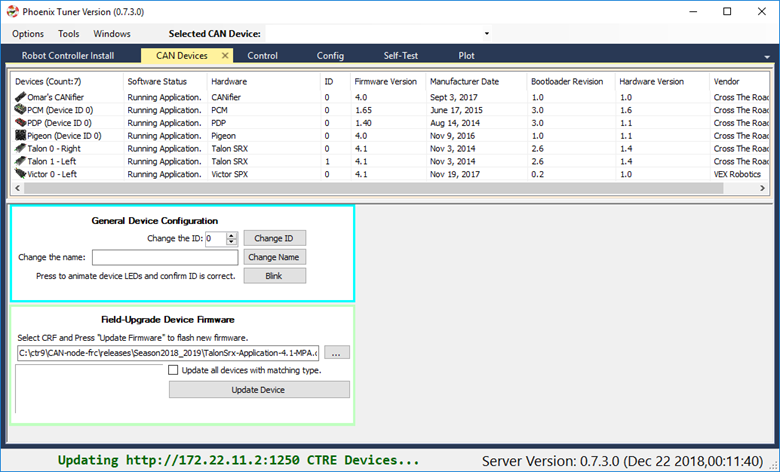

Phoenix-Tuner is the graphical interface that allows for configuration of Phoenix CAN bus devices.

It provides a variety of functionality to support all Phoenix CAN Bus devices. The feature set includes:

Update device firmware (including PDP/PCM)

Change CAN IDs

Configure direction and offsets

Self-test Snapshot devices

Change configuration settings

Factory default configuration settings

Test motors

Check plots

Temperature Calibrate Pigeon-IMU

Confirm proper CAN bus wiring without writing any software.

Now you can drive your motors and collect data without writing any software.

Configuration values can be checked, modified, and defaulted with the new config view. Config values can also be imported/exported as an easy-to-follow JSON formatted file.

The following sections of documentation will cover how to use Phoenix Tuner and the other components of Phoenix.

Tip

Have a feature request? Send to us at support@ctr-electronics.com or report it on GitHub.

Do I need to install any of this?¶

Yes, if any of the following:

You need library support for Talon SRX, Talon FX, Victor SPX, CANCoder, CANifier, Pigeon IMU

You need to field upgrade Talon SRX, Talon FX, Victor SPX, CANCoder, CANifier, Pigeon IMU, PDP, or PCM

You want to use Phoenix Tuner for CAN diagnostics (highly recommended)

Note

PCM and PDP objects are already supported in the base FRC installation. However, Phoenix Tuner is required for setting the device ID, field-upgrade, and Self-test Snapshot.

Prepare your workstation computer¶

Before Installing Phoenix…¶

It is strongly recommended to complete the base installation of FRC tools. https://docs.wpilib.org/en/latest/docs/getting-started/getting-started-frc-control-system/control-system-software.html

Warning

You will need to image the roboRIO to 2020 software before continuing. The roboRIO kickoff versions are image 2020_v10.

Test base FRC Installation - FRC LabVIEW¶

If a team intends to use LabVIEW to develop robot software, be sure to complete the full NI installer. At which point, opening LabVIEW should reveal the FRC-styled graphical start menu.

At this point it is recommended to create a simple template project and test deploy to the roboRIO. Be sure the DriverStation can communicate with the robot controller, and that DS message log is functional.

Note

LabVIEW is versioned 2019 due to its release schedule. Therefore, LV2019 is used for the 2020 season.

Test base FRC Installation - FRC C++ / Java¶

It is recommended to install the FRC Driver Station Utilities. This will install the Driver Station software, which is necessary for:

Basic comms checks

Reading joystick data

Generally required for enabling motor actuation (Phoenix Tuner Control features may require this, depending on setup).

General Recommendations for FRC C++ / Java.¶

The FRC C++/Java standard distribution for 2020 is based on the Microsoft Visual Studio Code development environment with WPI extensions.

If you are not familiar with developing C++/Java FRC programs, we strongly recommend testing full deployment to your robot controller before installing Phoenix and porting previous season software. A recommended test is to:

Create a project from scratch

Make a simple change such as add a print statement with a counter.

Deploy (or debug) your application.

Confirm robot can be teleop-enabled in DS.

Open FRC message Console and read through all the messages.

Repeat 2 - 5 ten times. This will train students to become familiar with and build general confidence in the tools.

Note

Third-party vendor libraries are installed into the C++/Java project, not the environment. For each C++/Java project you create, you must use the WPI provided tools to select Phoenix to bring the libraries into your project.

What to Download (and why)¶

Option 1: Windows installer (strongly recommended)¶

Environments: Windows-LabVIEW, Windows-C++/Java, HERO C#

Phoenix Installer zip can be downloaded at:

https://store.ctr-electronics.com/software/.

It is typically named Phoenix Framework_Windows_vW.X.Y.Z.zip

This will install:

The LabVIEW Phoenix API (if LabVIEW is detected and selected in installer)

The C++/Java Phoenix API (if selected in installer)

Device Firmware Files (that were tested with the release)

CTRE Support of RobotBuilder

Phoenix Tuner

Installs Phoenix API libraries into the roboRIO (required for LabVIEW)

Installs Phoenix Diagnostics Server into the RoboRIO (needed for CAN diagnostics).

Plotter/Control features

Self-test Snapshot

Device ID and field-upgrade

Option 2: Phoenix API via Non-Windows Zip¶

Environments: Linux/MacOS - C++/Java

The Phoenix API can be manually installed on non-Windows platforms by downloading the “non-Windows” zip and following the instructions found inside.

This essentially contains a maven-style repository that holds the API binaries and headers, as well as a “vendordeps” JSON file that instructs VS how to incorporate the Phoenix C++/Java API libraries.

Note

This is auto installed when using the Windows full installer (Option 1).

Phoenix Tuner¶

Environments: Windows

If you are using option 2, you will need to download Phoenix Tuner separately. Phoenix Tuner is available here… https://github.com/CrossTheRoadElec/Phoenix-Tuner-Release/releases

This can be convenient for workstations that aren’t used for software development, but are used for field-upgrade or testing motor controllers.

Note

LabVIEW teams may need to use Phoenix Tuner to install Phoenix libraries into the roboRIO. More information on this can be found under Prepare Robot Controller.

Note

This is auto installed when using the Windows full installer.

Note

Developers may be interested to know that all Phoenix Tuner features leverage an HTTP API provided by the Phoenix Diagnostics Server. As such, custom tooling can be developed to field-upgrade, test-control, or diagnostics CTRE devices without Tuner.

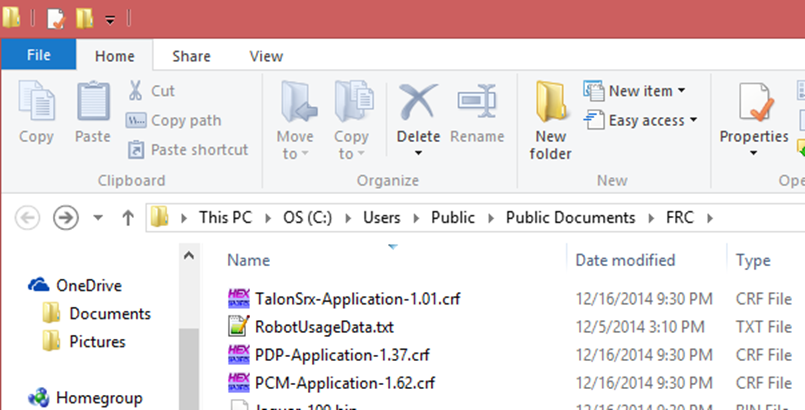

Device Firmware Files (crf)¶

The test firmware files for all CTRE devices are packaged with the Windows Installer (and has been for years). However, many FRC teams don’t notice, or prefer to download them directly from the product pages on the ctr-electronics.com website. If Internet access is available, they can be downloaded as such.

The FRC Software installer will create a directory with various firmware files/tools for many control system components. Typically, the path is:

C:\Users\Public\Documents\FRC

When the path is entered into a browser, the browser may fix-up the path:

C:\Users\Public\Public Documents\FRC

In this directory are the initial release firmware CRF files for all CTRE CAN bus devices, including the new Talon FX and CANCoder.

The latest firmware to be used can be found in the Software Release Notes.

Note

Additionally, newer updates may be provided online at https://store.ctr-electronics.com/software/.

Note

There is no longer FRC versus non-FRC firmware for motor controllers. Instead the latest firmware detects if the use case is FRC. If so, the device will FRC-Lock, and will require the Driver Station for actuation.

Workstation Installation¶

There are three installation methods listed below. The simplest and recommended approach is to run the Windows Installer (Option 1).

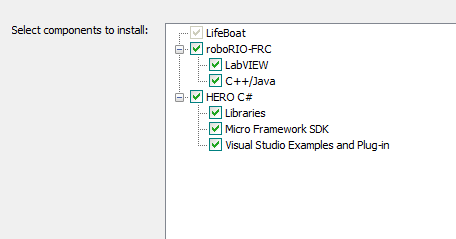

Option 1: Windows Offline Installer (C++/Java/LabVIEW, HERO C#)¶

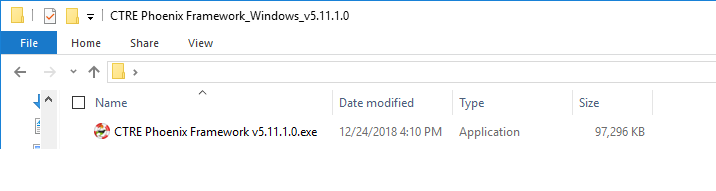

Un-compress the downloaded zip.

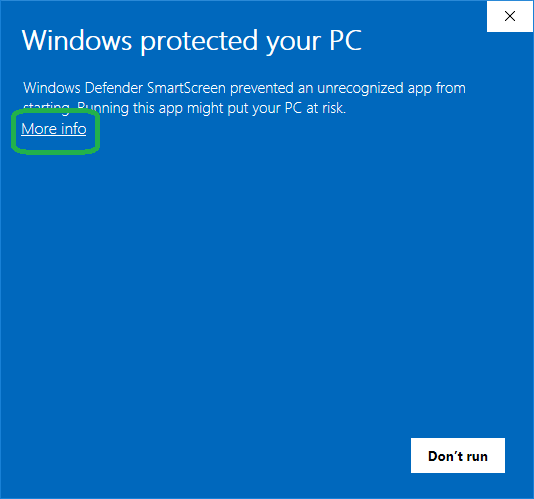

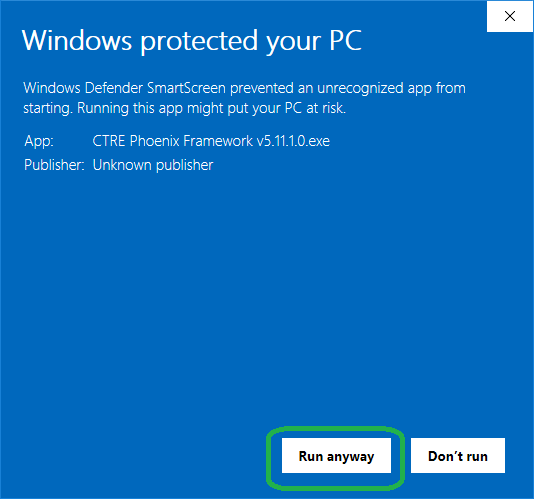

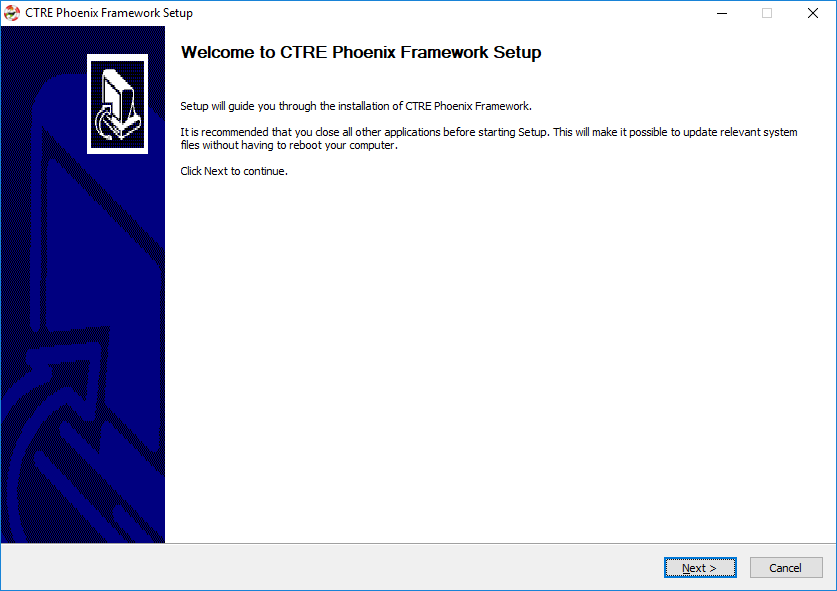

Double click on the installer. If the Windows protection popup appears press More Info, then Run anyway.

This will look very similar to previous installers - make sure you have the relevant component selected for your programming language.

LV Teams: Make sure LabVIEW is selected. If it is grayed out, then LabVIEW was not installed on the PC.

C++/Java Teams: Make sure C++/Java is selected.

If Visual Studio 2017 (Community/Professional) is detected, HERO C# will be selected. This can be turned off to speed up the installer.

Installer can take anywhere from 30 seconds to 5 minutes depending on which Microsoft runtimes need to be installed.

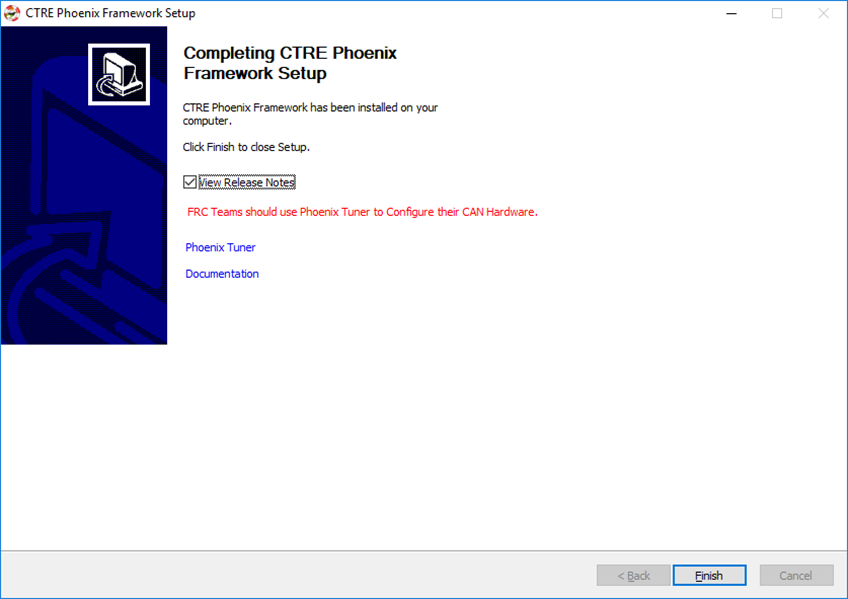

Final page will look like this. The Phoenix Tuner link can be used to open Phoenix Tuner. Alternatively, you can use the Windows Start Menu.

Option 2: Non-Windows Zip (C++/Java)¶

The zip will contain two folders, “maven” and “vendordeps”. These folders are meant to be inserted into your frc2020 install folder.

See WPI documentation for typical location. https://docs.wpilib.org/en/latest/docs/software/wpilib-overview/3rd-party-libraries.html#the-mechanism-c-java

Copy/paste the maven and vendordeps folder into frc2020 folder. This will override a pre-existing Phoenix installation if present.

Note

This will not install Phoenix Tuner or firmware files. If these are necessary (and they typically are) these can be downloaded separately or consider using the complete Phoenix Installer.

Post Installation Steps¶

After all workstation installs, the following checks should be followed to confirm proper installation.

FRC C++/Java - Verify Installation¶

The offline files for vscode are typically installed in:

C:\Users\Public\wpilib\2020\vendordeps\Phoenix.json (File used by vscode to include Phoenix in your project)

C:\Users\Public\wpilib\2020\maven\com\ctre\phoenix (multiple maven-style library files)

Your drive letter may be different than “C:”. After running the Phoenix Installer, the instructions to add or update Phoenix in your robot project must be followed.

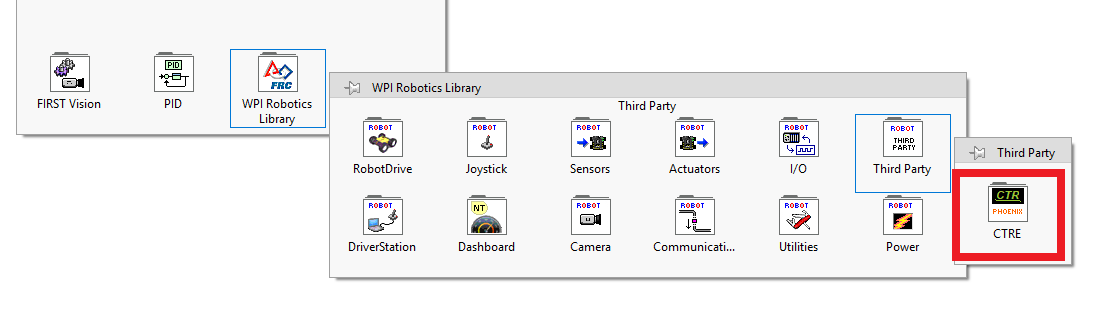

FRC LabVIEW – Verify Installation¶

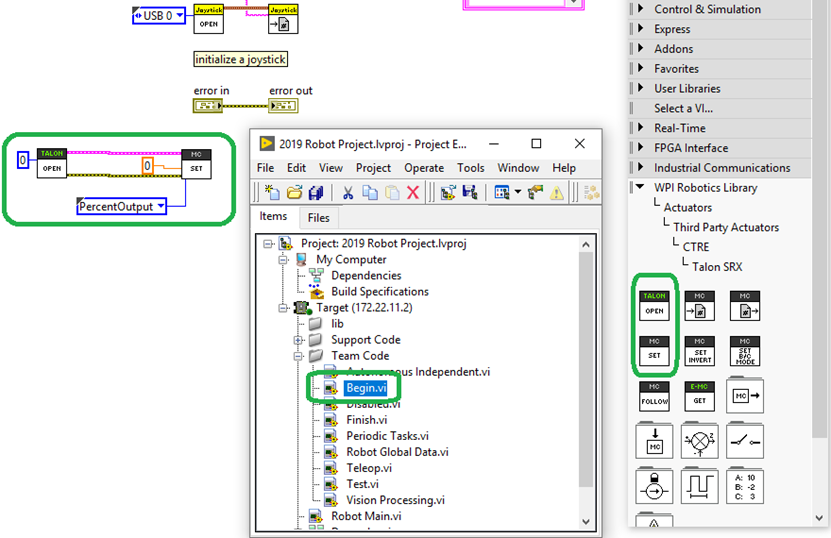

After running the installer, open a pristine copy of FRC LabVIEW.

Testing the install can be done by opening LabVIEW and confirming the VIs are installed. This can be done by opening an existing project or creating a new project, or opening a single VI in LabVIEW. Whatever the simplest method to getting to the LabVIEW palette.

The CTRE Palette is located in:

WPI Robotics Library -> Third Party.

This palette can also be found in:

WPI Robotics Library -> RobotDrive -> MotorControl -> CanMotor

WPI Robotics Library -> Sensors -> Third Party

WPI Robotics Library -> Actuators -> Third Party

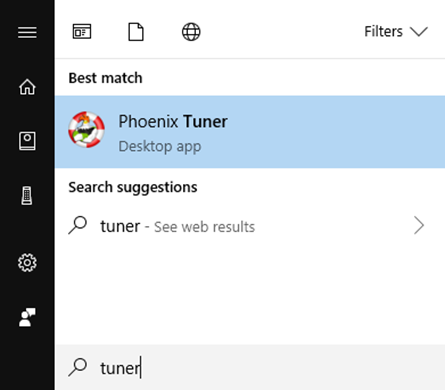

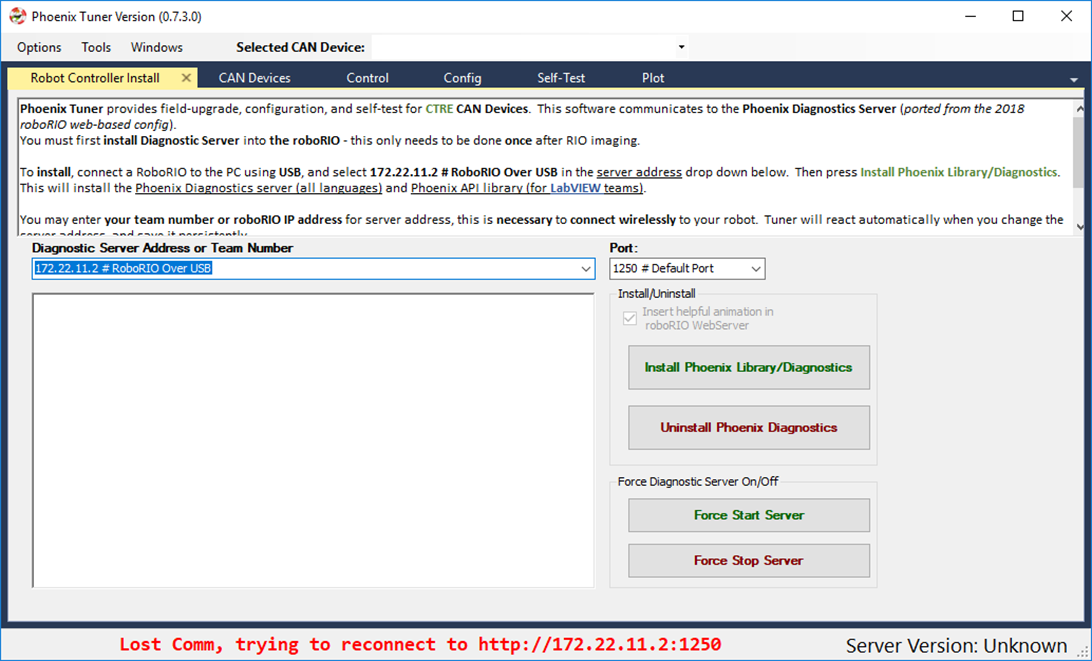

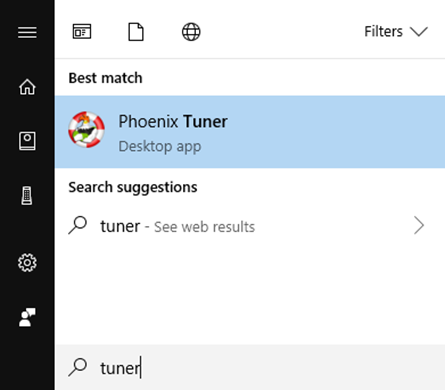

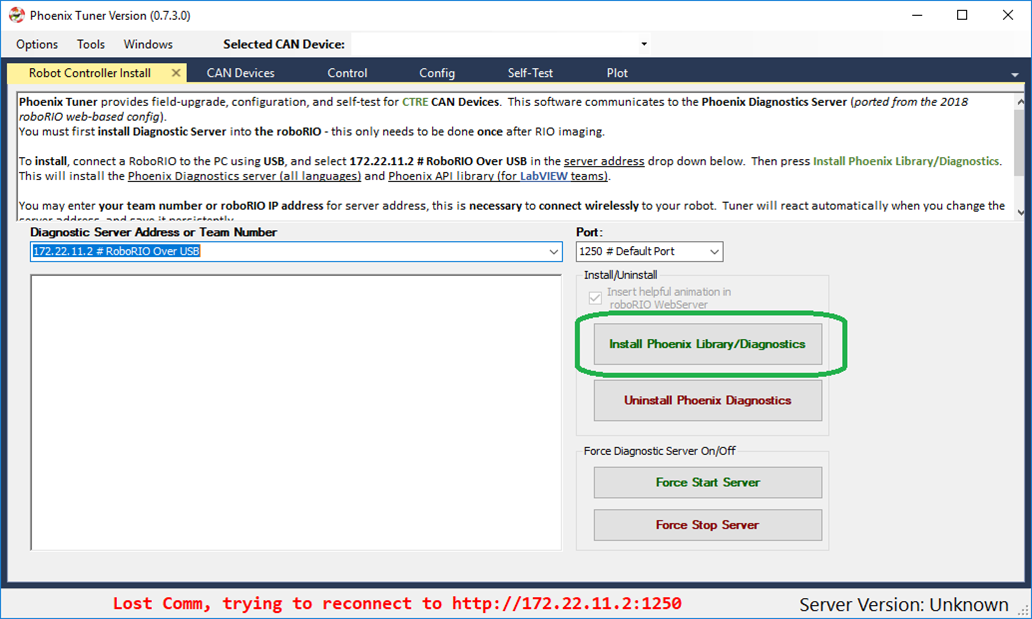

FRC Windows – Open Phoenix Tuner¶

Open Phoenix Tuner

If this is the first time opening application, confirm the following:

the status bar should read “Lost Comm”.

No CAN devices will appear.

The Server version will be unknown.

FRC: VS Code C++/Java¶

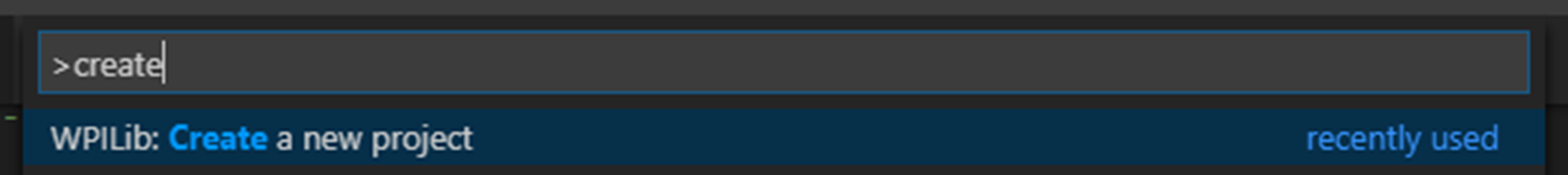

FRC C++/Java – Create a Project¶

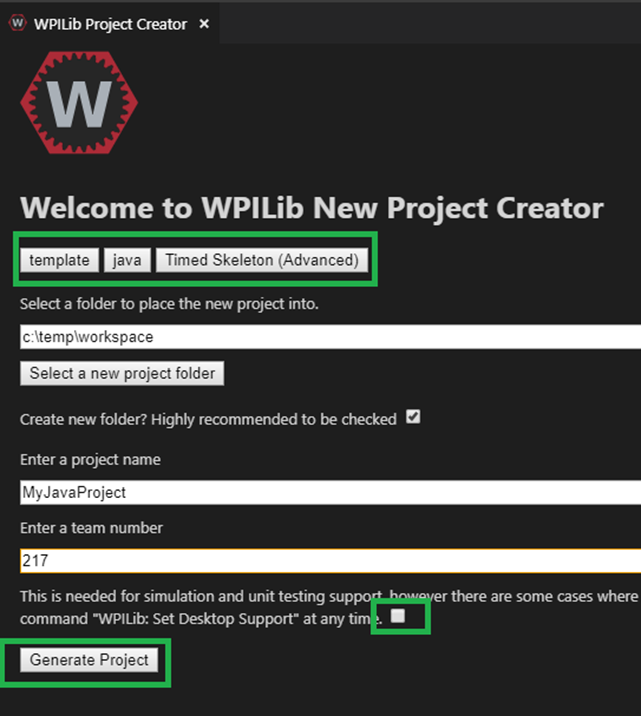

Next we will create a new robot project in vscode and create a Talon SRX. The goal is compile the project only, so hardware is not needed.

Follow the WPI frc-docs instructions on reaching the create new project. Typically, you can use CNTRL+SHIFT+P to open the VS text bar, and type create to reach the WPI command.

Make sure the desktop checkbox is cleared, Phoenix does not currently support desktop simulation. “Timed Skeleton” is used in this example for sake of simplicity.

Once the project is created, ensure project builds. Testing robot deploy is also useful if robot controller is available.

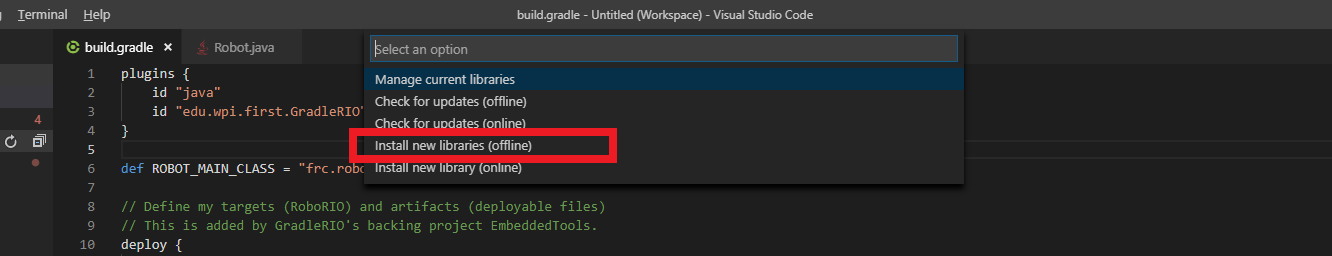

FRC C++/Java – Add Phoenix¶

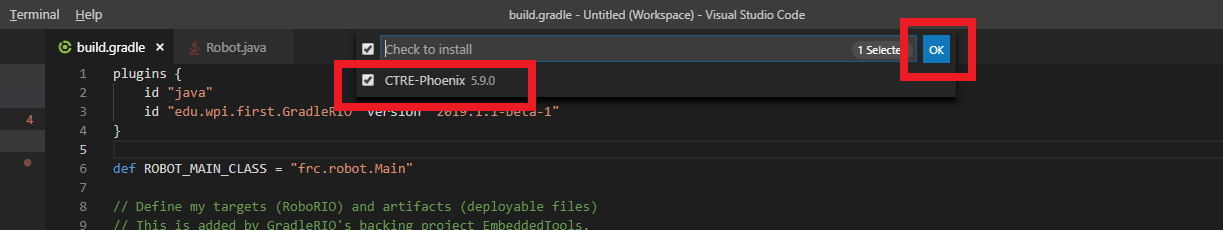

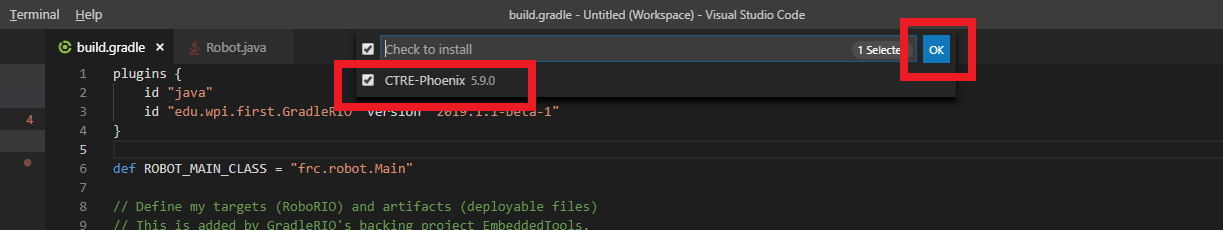

Right-Click on “build.gradle” in the project tree, then select “Manage Vendor Libraries”.

At the top of your screen, a menu will appear. Select “Install new libraries (offline)”.

Tip

Alternatively you can use “Install new libraries (online)” option with https://maven.ctr-electronics.com/release/com/ctre/phoenix/Phoenix-frc2022-latest.json. However this is not recommended as this requires a live Internet connection to use your FRC project.

The menu will now display a list of vendor libraries you can install. Check “CTRE Phoenix”, then click “OK”

Note

This will bring the library into the project references, however the library will not be loaded if the source code does not create a Phoenix object or call any Phoenix routines. Therefore, you must create a Phoenix object to properly test the install.

Tip

Teams can verify Phoenix is in their robot project by checking for the existence of vendordeps/Phoenix.json in the project directory.

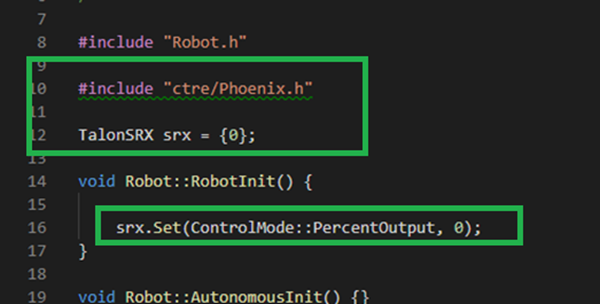

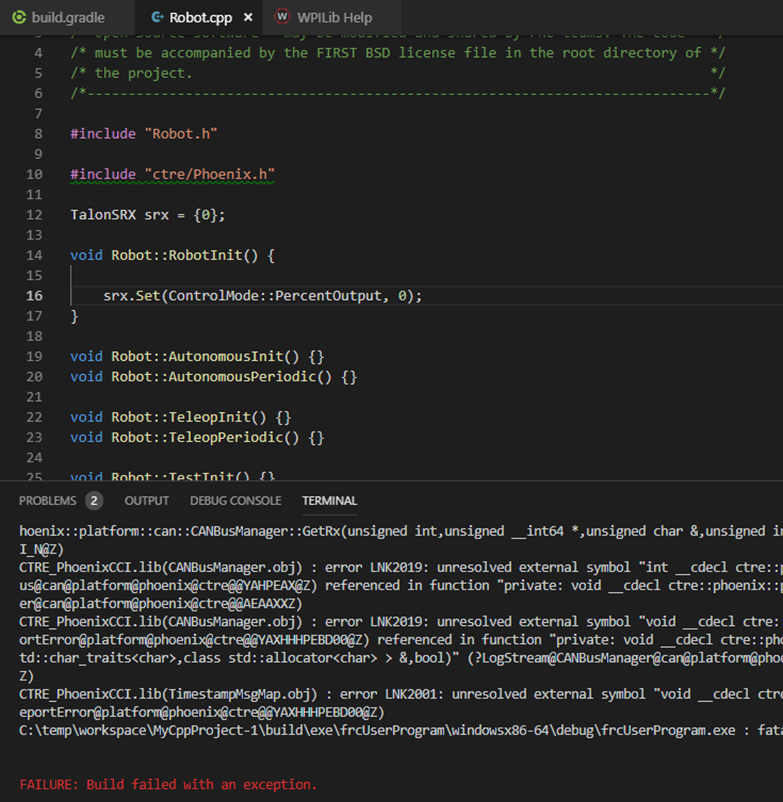

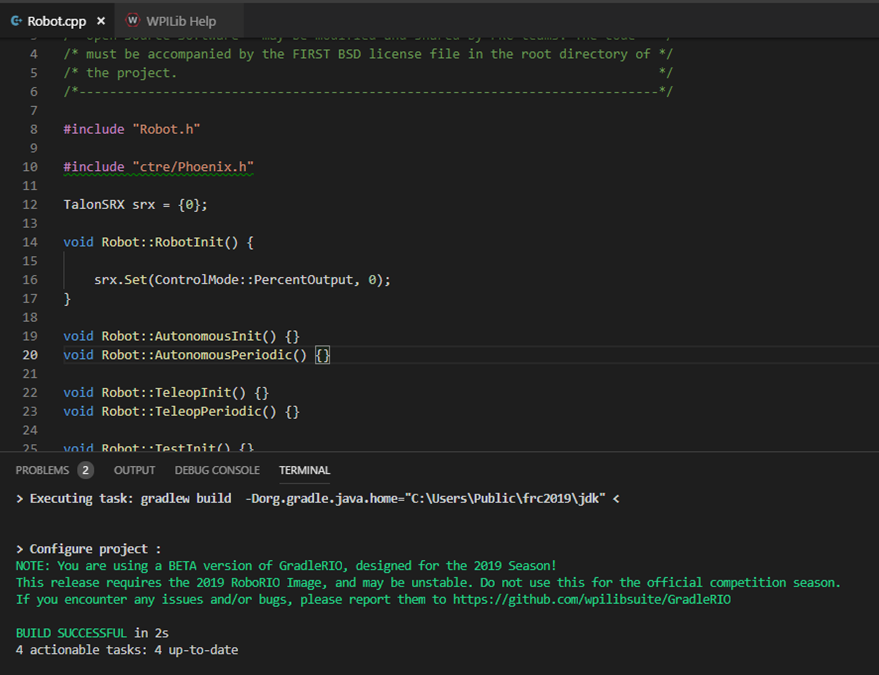

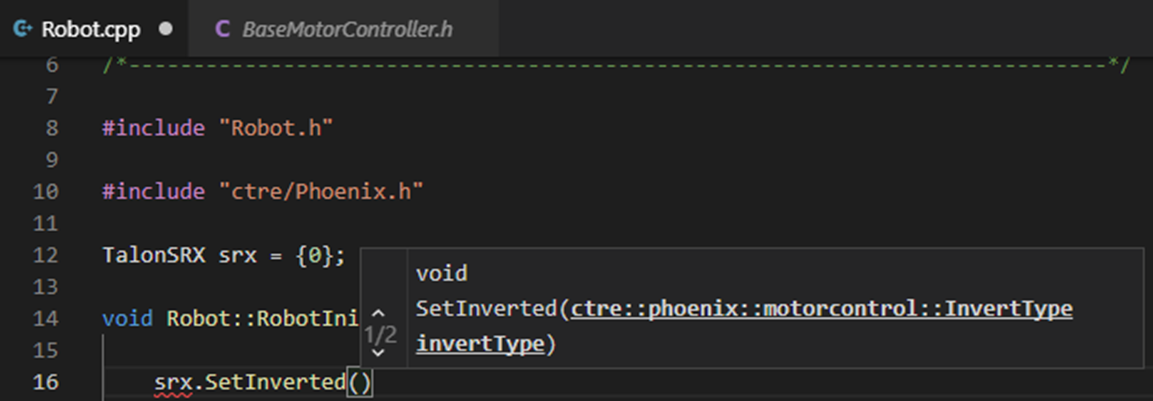

FRC C++ Build Test: Single Talon¶

Create a TalonSRX object. The number specified is the Talon’s device ID, however for this test, the device ID is irrelevant.

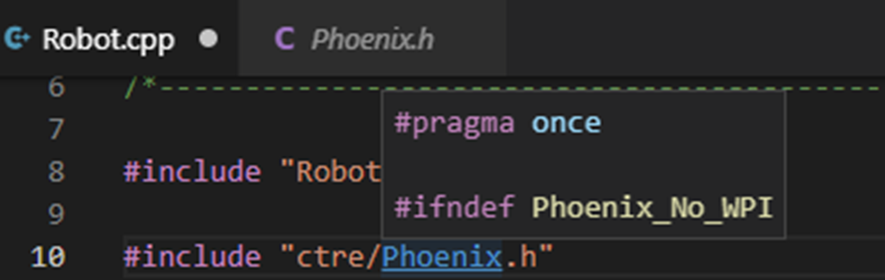

Be sure to include “ctre/Phoenix.h”, otherwise TalonSRX will not be recognized as a valid class type.

Add an example call, take your time to ensure to spell it correctly.

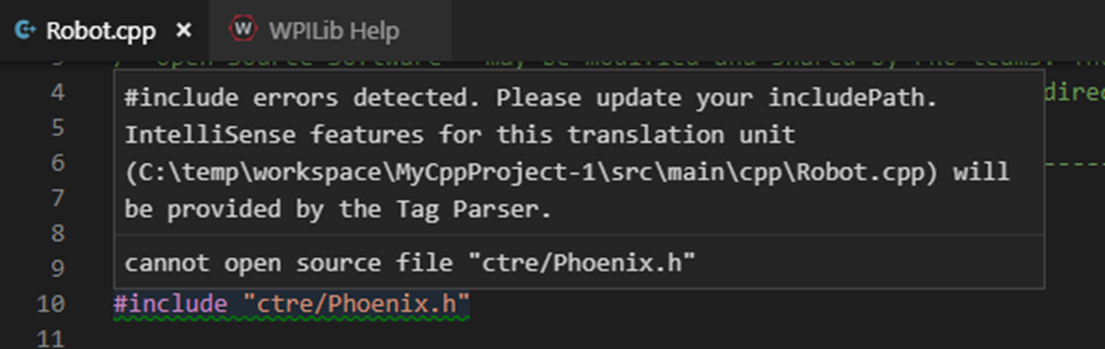

Intellisense may not be functional at this point in time (note the green underline indicating VS did not parse the header).

Tip

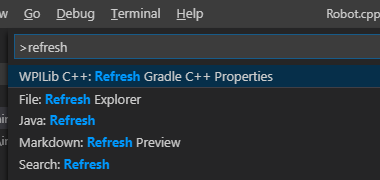

To correct this - Close all files in the project - Restart VS Code - Wait ~40s - Reopen source files in VS Code

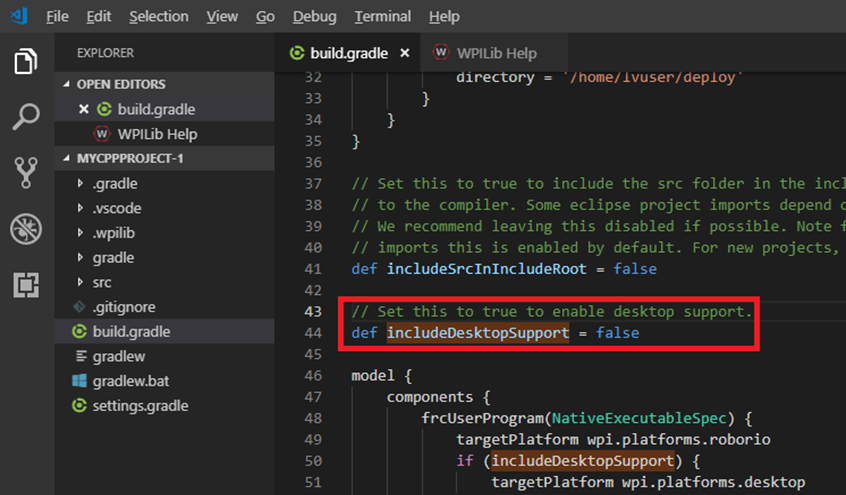

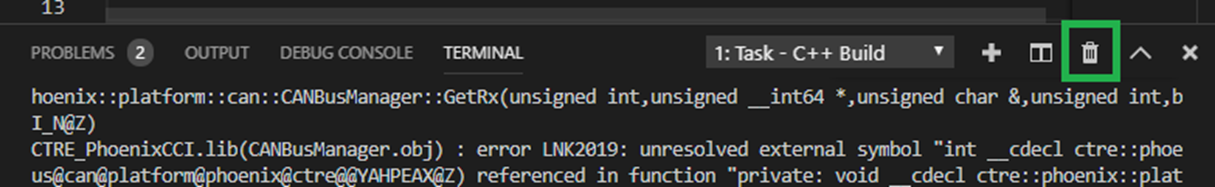

If you see linker errors, then the desktop simulation checkbox was likely checked.

This can be resolved by manually turning off the feature. Set flag to false.

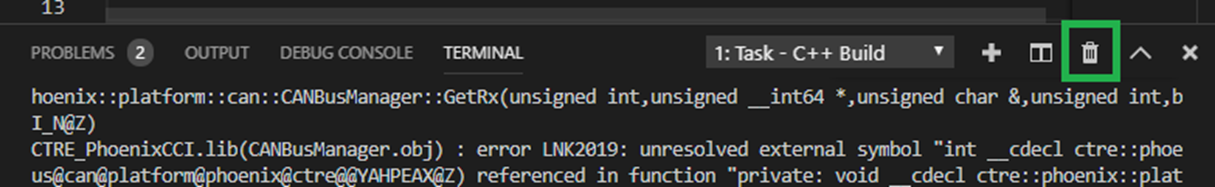

Tip

When resolving compiler/linker errors, press the trash icon first to cleanly erase the previous error lines in the terminal. Or manually scroll the bottom to ensure you are not looking at stale error lines from previously failed builds.

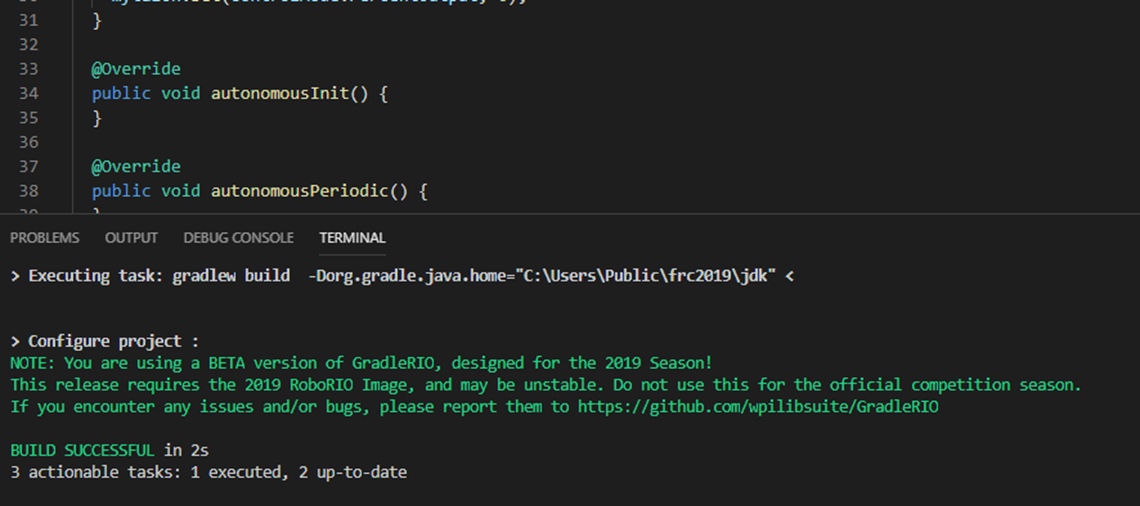

The only reliable way to confirm build was successful is to confirm the BUILD SUCCESSFUL line at the bottom of the TERMINAL.

Note

The problems tab may or may not be clear of errors. Our testing with VSCode has shown that it can report stale or incorrect information while making code changes. Always use the TERMINAL output to determine the health of your compilation and build system.

In the event that the intellisense is not resolving symbols (for IDE auto-complete features), restart VSCode.

After restart, routines should be found correctly.

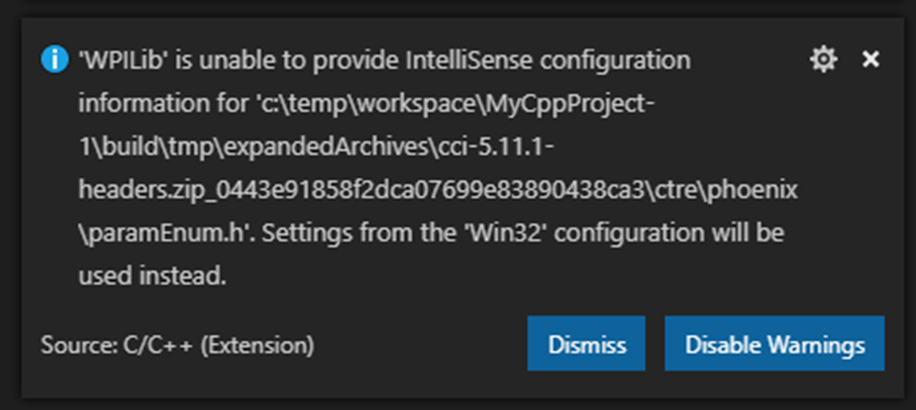

Tip

Headers can be auto-opened by CNTRL+CLICK the include line.

Depending on the version of VS Code used, you may encounter an IntelliSense warning. These can be ignored.

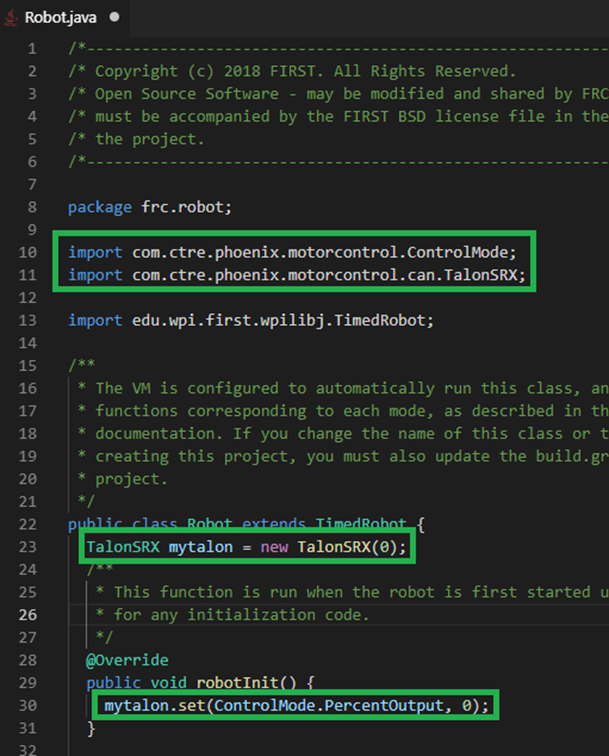

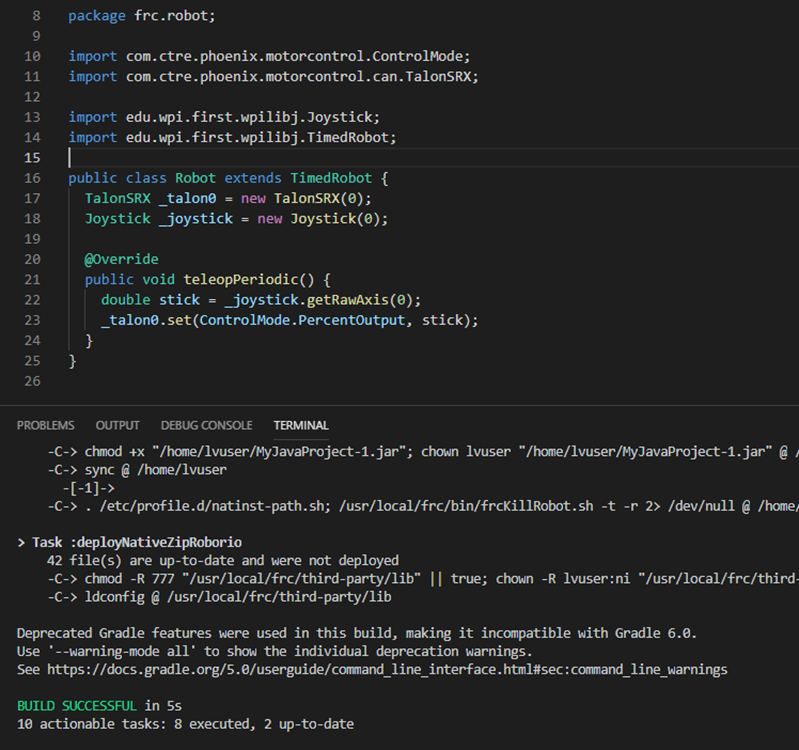

FRC Java Build Test: Single Talon¶

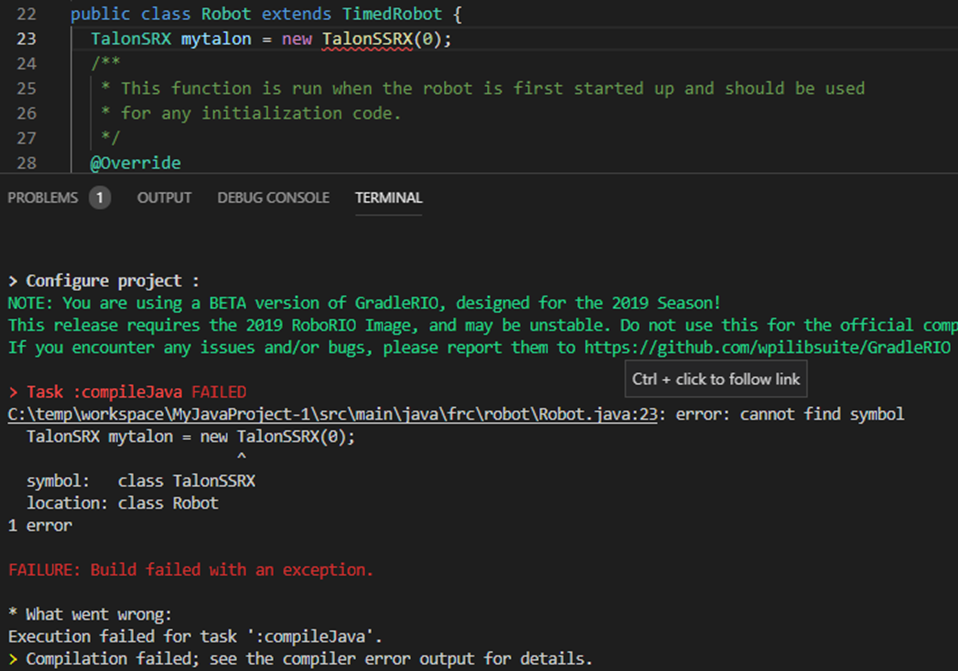

Create a TalonSRX object. The number specified is the Talon’s device ID, however for this test, the device ID is irrelevant.

Typically, you can type “TalonSRX” and watch the intellisense auto pop up. If you press ENTER to select the entry, the IDE may auto insert the import line for you.

Add an example call, take your time to ensure to spell it correctly. Use the intellisense features if available.

Here is the final result.

If you see build errors, carefully find the first erroneous line in the TERMINAL output. Typically, you can CNTRL + click the error line and auto-navigate to the source.

When resolving compiler errors, press the trash icon first to cleanly erase the previous error lines in the terminal. Or manually scroll the bottom to ensure you are not looking at stale error lines from previously failed builds.

The only reliable way to confirm build was successful is to confirm the BUILD SUCCESSFUL line at the bottom of the TERMINAL.

Note

The problems tab may or may not be clear of errors. Our testing with VSCode has shown that it can report stale or incorrect information while making code changes. Always use the TERMINAL output to determine the health of your compilation and build system.

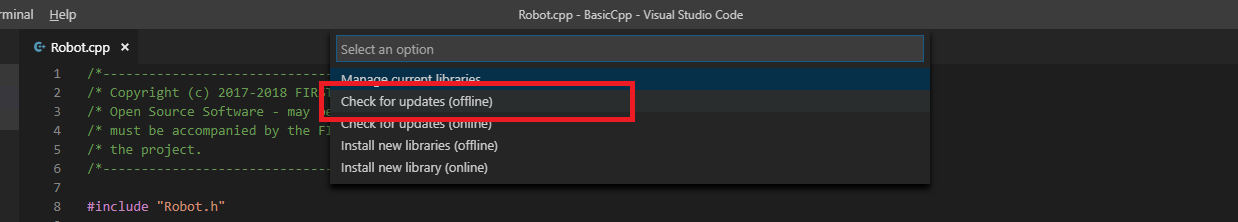

FRC C++/Java - Updating Phoenix¶

If you already have a previous version of Phoenix installed and you want to update to a newer version, follow these steps. Install the latest version of Phoenix on your PC. Basically, rerun the latest installer (same as section above).

Open your robot program in VS Code.

At the top of your screen, a menu will appear. Select “Check for updates (offline)”.

Tip

Alternatively you can use “Check for updates (online)”. However this is not recommended as this requires a live Internet connection to use your FRC project.

The menu will now display a list of vendor libraries you can update. Check “CTRE Phoenix”, then click “OK”

FRC C++/Java – Test Deploy¶

Create a Talon SRX (or Pigeon, CANifier, Victor SPX) and attempt to “deploy”. Adding a print statement also helps to confirm you are actually deploying the software displayed in VsCode. Confirm that the software deployed using DriverStation. DS may report firmware-too-old / not-retrieved errors since the hardware has not been setup yet.

FRC: Prepare NI roboRIO¶

Why prepare Robot Controller?¶

In the previous 2019 season, preparing the Robot Controller typically meant:

Installing the Phoenix Diagnostics

Installing the Phoenix API into roboRIO (if using LabVIEW).

In the 2020 release of Phoenix, both of these are automatically handled by the library deployment features of WPI Visual Studio Code extensions (C++/Java) and NI LabVIEW.

Phoenix Diagnostics has become a library that is compiled into the FRC robot application. This is a result of the roboRIO CAN bus changes implemented by the NI for 2020. Tuner now communicates with “Phoenix Diagnostic Server” running in the deployed application via an HTTP API.

If the roboRIO does not have a deployed application, a temporary Diagnostic Server application can be deployed from Tuner. This is particularly useful during hardware-bringup.

LabVIEW¶

NI LabVIEW supports a feature that will automatically deploy the Phoenix API libraries to the roboRIO. After running the installer, 2020 LabVIEW robot projects will automatically install Phoenix into the roboRIO when the program is permanently deployed via “Run As Startup”.

- The steps for first deploy are:

“Build” the FRC Boot-up Deployment

“Run as Startup”

Re-boot the roboRIO (see note below)

Note

After first Run-as-Startup (since imaging the RIO), you may see an error in the Driver Station reporting that the Phoenix libraries are missing. A reboot of the RIO will likely resolve this. We recommend using the “Restart roboRIO” button in the Driver Station.

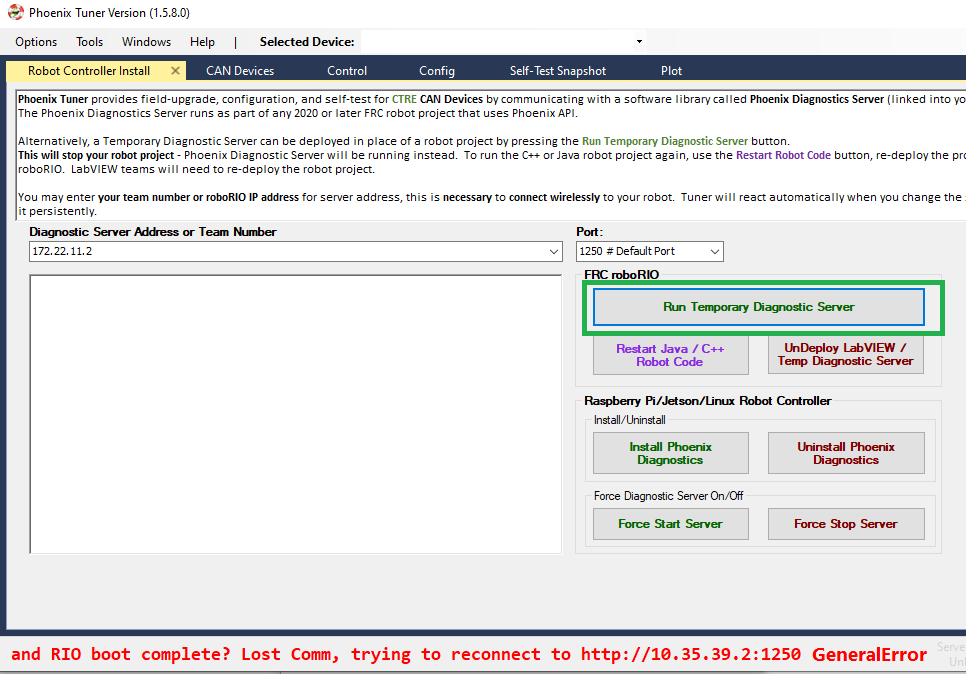

How to prepare Robot Controller¶

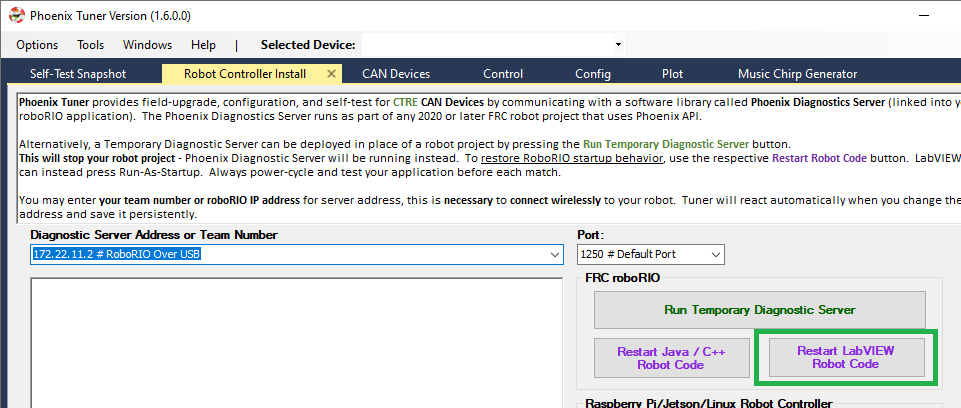

Open Tuner and connect USB between the workstation and the roboRIO.

Select 172.22.11.2 # RoboRIO Over USB and 1250 for the address and port. These are generally selected by default, and typically do not require modification.

Deploy the Temporary Diagnostic Server.

Note

This is unnecessary if a robot application has been deployed already (C++, Java, or LabVIEW).

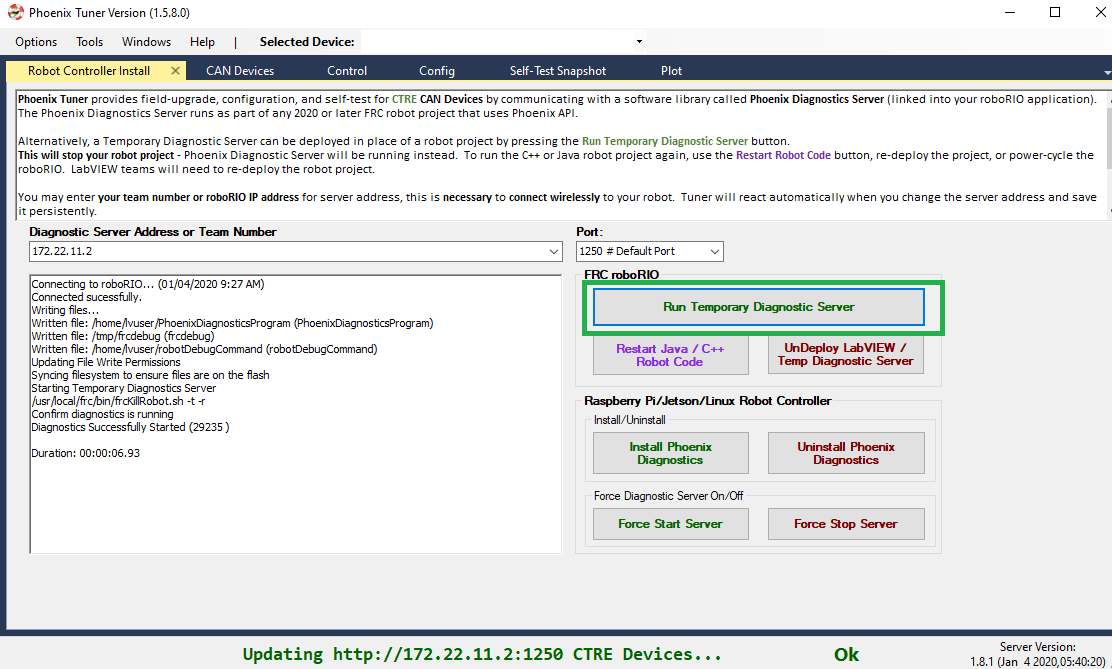

Verify the robot controller - Tuner¶

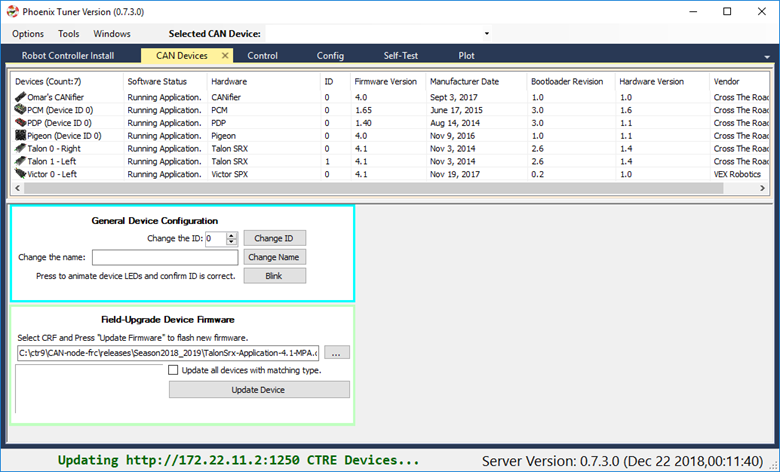

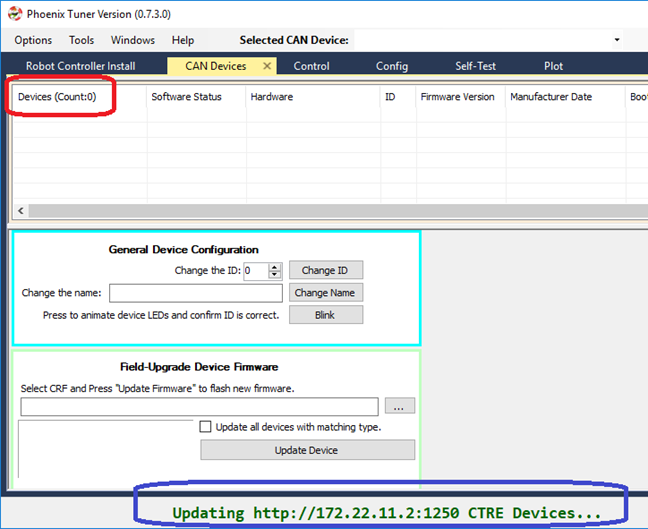

After application deployment, Tuner will immediately connect to the roboRIO.

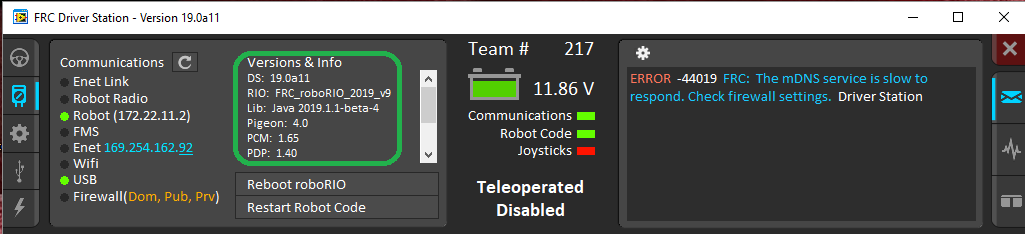

Confirm the bottom status bar is green and healthy, and server version is present.

If there are CAN device present, they will appear. However, it is possible that devices are missing, this will be resolved in the next major section (CAN Bus bring up).

roboRIO Connection (Wi-Fi/Ethernet)¶

The recommended connection method for control/plotter features is over USB or using static IP (Ethernet/Wi-Fi). The mDNS strategy used by the roboRIO can sometimes fail intermittently which can cause hiccups when submitting HTTP requests to the roboRIO.

Testing has shown that using USB (172.22.11.2) or using static IP address has yielded a greater user experience than the roborio-team-frc.local host name has.

Note

Future releases may have improvements to circumvent the limitations of mDNS.

Verify the robot controller - LabVIEW¶

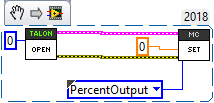

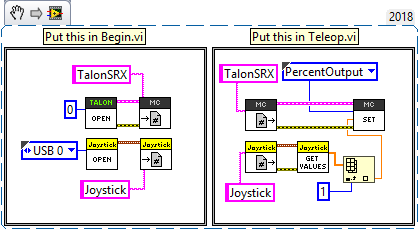

Create a pristine LabVIEW application. Add a CTRE device to Begin.Vi. For example, create a Talon SRX object, even if the device is not physically present.

Tip

Drag drop the following into your Begin.vi

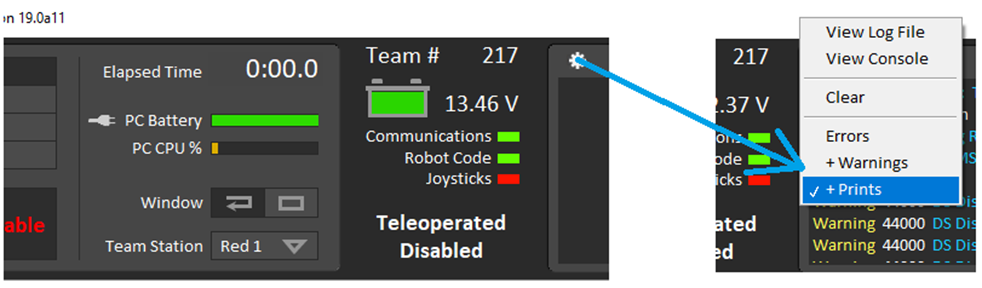

Connect DS and turn on Warnings and Prints by selecting the bottom most option.

Upload the application to the robot controller and check the driver station message log.

If everything is working, the Phoenix Initialization message can be found.

Note

This message will not appear after subsequent “soft” deploy (LabVIEW RAM-only temporary deploys).

If Phoenix API has not been installed into the robot controller, this message will appear.

If you have used Phoenix LifeBoat (which should NOT be used), this message will appear. If this occurs you will need to re-image your roboRIO and then re-follow the instructions in this section exactly, without using LifeBoat.

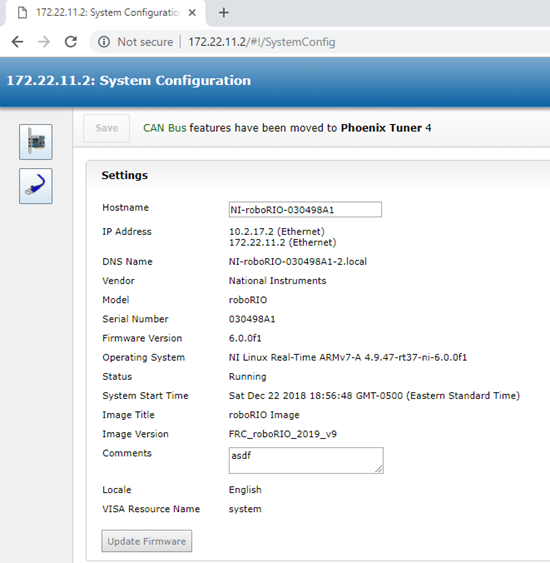

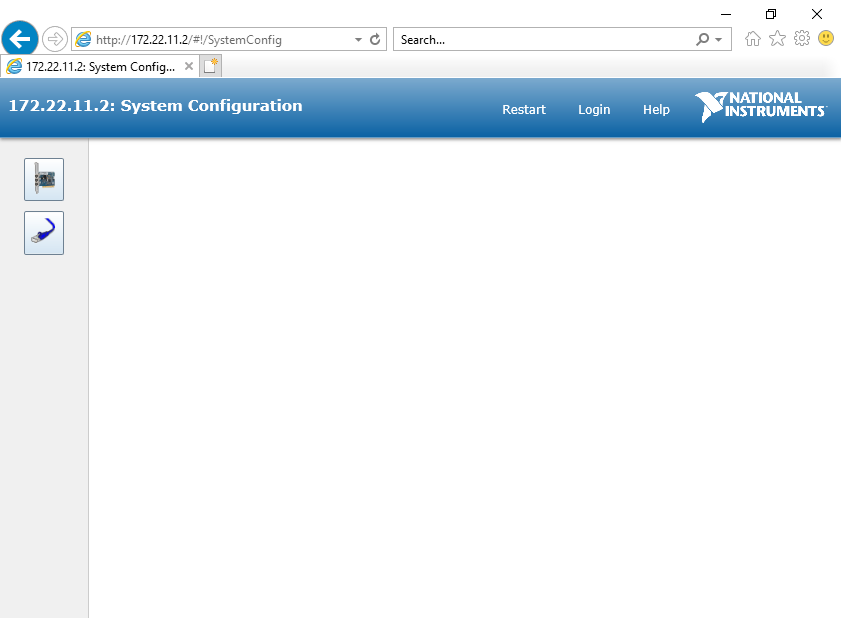

Verify the robot controller - Web page¶

The Silverlight web interface provided in previous seasons is no longer available. Moving forward, the NI web interface will likely be much simpler.

As a result, Phoenix Tuner may embed a small message reminder indicating that CAN features have been moved to Tuner. This will depend on the version of Phoenix.

Typically, the message will disappear after 5 seconds. This will not interfere with normal web page features (IP Config, etc.).

Warning

The roboRIO Web-page does not provide CAN bus support any more as this has been removed by NI. Use Phoenix Tuner instead.

Warning

The roboRIO Web-page does not render correctly if using Internet Explorer (see below). Recommended browsers are Chrome or Firefox.

Verify the robot controller - HTTP API¶

Tuner leverages the HTTP API provided by Phoenix Diagnostics Server.

So technically you have already confirmed this is working.

But, it is worth noting that this HTTP API can potentially be used by third-party software, or even the robot application itself.

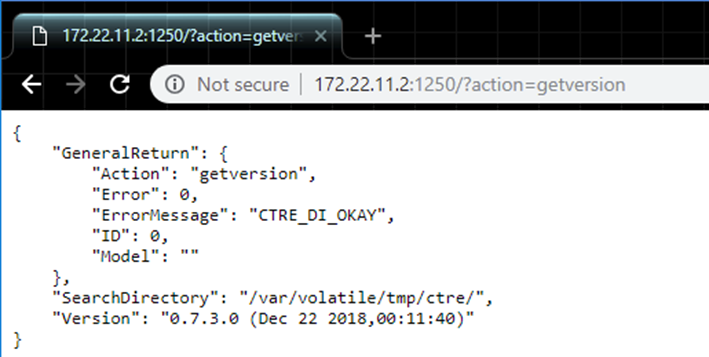

Here is a simple get version command and response.

http://172.22.11.2:1250/?action=getversion

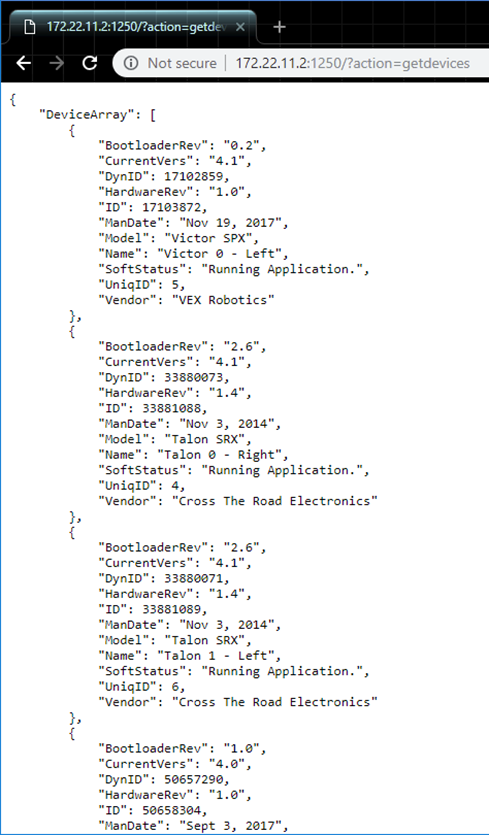

Here is a simple getdevices command and response.

http://172.22.11.2:1250/?action=getdevices

Prepare Linux Robot Controller¶

Why prepare Linux Robot Controller?¶

Preparing a Linux robot controller allows CAN Device control without a roboRio for non-FRC use or as a secondary processor that can also directly control CAN Devices while still using the roboRIO for Enable/Disable Signal.

Phoenix Diagnostic Server is necessary for Phoenix Tuner to interact with CTRE CAN Devices. Tuner communicates with “Phoenix Diagnostic Server”, a Linux application that provides an HTTP API.

Supported Linux Controllers¶

Below are the currently supported Linux hardware platforms. An additional SocketCAN device is necessary to utilize the provided software as-is, otherwise a custom platform library is required.

NVidia Jetson TX2

NVidia Jetson Nano

Raspberry Pi 3

Raspberry Pi 4

It is possible to use other hardware platforms, however hardware and software setup may be different than this documentation.

Note

CTRE currently recommends the CANable for use as a SocketCAN device. More information can be found here: https://canable.io/

How to prepare Hardware?¶

Jetson TX2¶

Follow the documentation provided by NVidia to setup the Jetson TX2: https://developer.nvidia.com/embedded/downloads

Raspberry Pi/Jetson Nano¶

Image your device with the respective image below. Other Images can also be used, although these images have been tested and are known to be supported.

Raspbian Buster Image for Raspberry Pi: Pi Image

Jetson Nano Developer Kit SD Card Image: Nano Image

Etcher (available here) is the recommended tool for flashing the image to an SD card. With Etcher open, select your downloaded image and the SD card target, then click “Flash!”.

Once flashed insert the SD card into your device, set up a user and connect to a Wi-Fi network.

CANable (SocketCAN Device)¶

Once your controller is ready, it is necessary to setup your SocketCAN device.

To use CANable as a SocketCAN device, update the Canable firmware to “candlelight” using these instructions.

Alternatively you can deploy SocketCAN firmware to a HERO. See our repository on Github.

How to prepare Robot Controller Software?¶

It is recommended to update your Linux platform software before installing the components necessary for Phoenix.

sudo apt-get update

sudo apt-get upgrade

Next, install the required software packages using the following commands:

CAN Tools

sudo apt-get install can-utilsGit

sudo apt-get install gitcmake (for build support)

sudo apt-get install cmakelibsdl2 (for gamepad support)

sudo apt-get install libsdl2-dev

With the necessary software installed, clone the example repository into the user directory. This example is a basic C++ project that includes all necessary Phoenix libraries and will be used to validate the hardware and software setup.

From the user directory, run: git clone https://github.com/CrossTheRoadElec/Phoenix-Linux-SocketCAN-Example.git

Then navigate into the repo directory: cd ./Phoenix-Linux-SocketCAN-Example/.

To ensure the scripts from our cloned repository can be executed, make sure to enable execution privileges.

chmod +x build.sh

chmod +x clean.sh

chmod +x canableStart.sh

Now we can initialize our SocketCAN interface.

Bring up the interface as socket “can0” by running the CANable start script:

./canableStart.sh

Note

if you see the message Device or resource busy it means the CAN network is already up and requires no further action.

Configure SocketCAN to allow hot swapping¶

This is necessary to be able to disconnect and reconnect your USB to CAN adapter without running bringing up the CAN network each time your usb to can adapter is reconnected.

Open a new terminal and type cd /etc/network/..

Once inside the network directory type sudo gedit interfaces.

sudo geany interfaces to edit the file.A text editor should open. Add the following lines to the file:

allow-hotplug can0

iface can0 can static

bitrate 1000000

txqueuelen 1000

up /sbin/ip link set $IFACE down

up /sbin/ip link set $IFACE up type can

How to validate SocketCAN functionality?¶

Make sure you have at least one CTRE CAN device connected for validation of the CAN network. With no CAN traffic, device LEDs will be blinking RED.

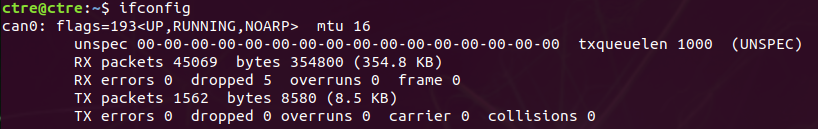

Use the ifconfig command to list network interfaces, where you can see the status of the CAN socket.

The interfaces list should contain an entry for “can0” and should look like this:

Type cansend can0 999#DEADBEEF to send a test CAN frame. Your CAN devices should now blink orange since a valid CAN message has been seen.

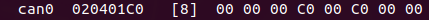

Use candump can0 to see all incoming CAN traffic, which should display all periodic information being sent by a CAN Device.

You should see a constant stream of messages similar to this:

Running the SocketCan Example¶

Build the example with ./build.sh.

Then run the example with ./bin/example.

You’re now running Phoenix on your Linux device. Confirm there are no error messages being sent to console output.

Note

You may see error messages if your CAN devices are not yet configured and firmware updated. Follow the Bring Up: CAN section to setup your CAN devices.

Warning

If your CTRE CAN devices were previously used with a roboRIO it is likely they are FRC locked and will not enable without a roboRIO on the CAN bus. See Confirm FRC Unlock for instructions to confirm FRC unlock.

You can stop your Program with Ctrl+z.

Modifying the SocketCan Example¶

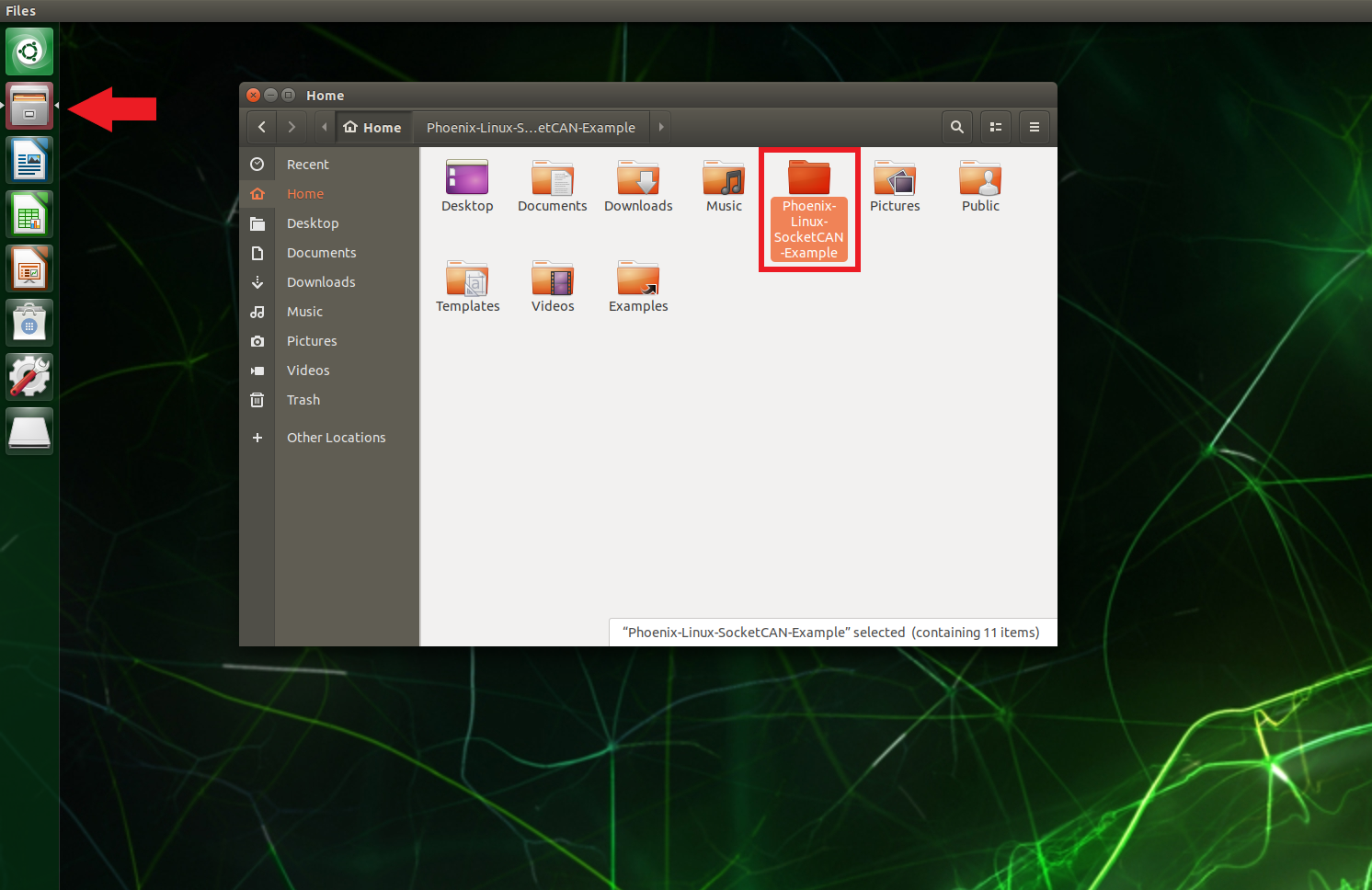

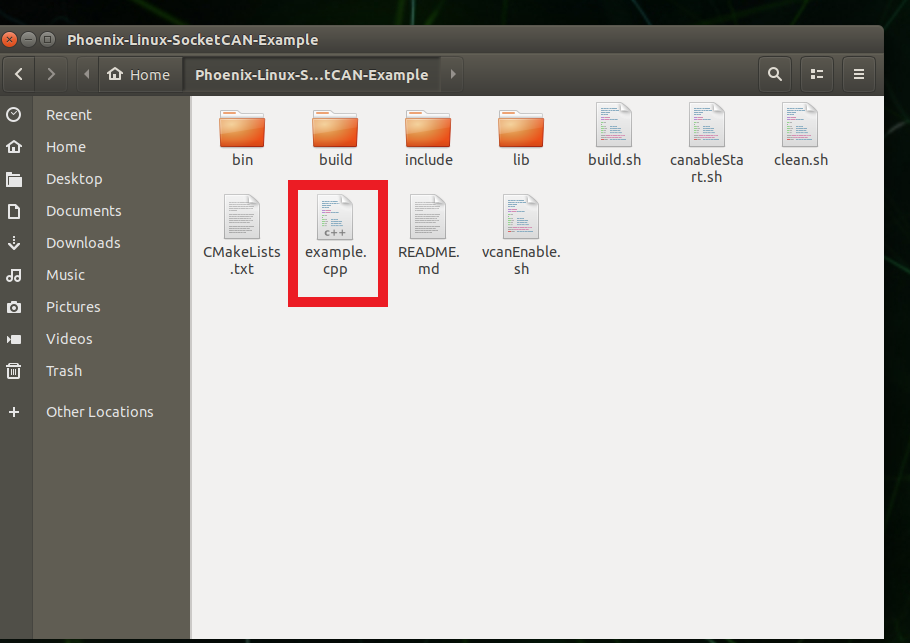

To modify the example Open the file explorer and navigate to the Phoenix-Linux-SocketCAN-Example folder.

The example is a simple program, so all of the code is contained within example.cpp. Edit this file to modify the program.

After modifying the file click the Save button in the top right corner then Go back to Running the SocketCAN Example to run your modified example.

How to setup Phoenix Tuner?¶

With the CAN network up and running, Phoenix Tuner can be used with the Linux Robot Controller in the same manner as the roboRIO.

Note

SSH must be enabled on the Linux Robot Controller to perform a field upgrade or modify a device’s configuration using Phoenix Tuner.

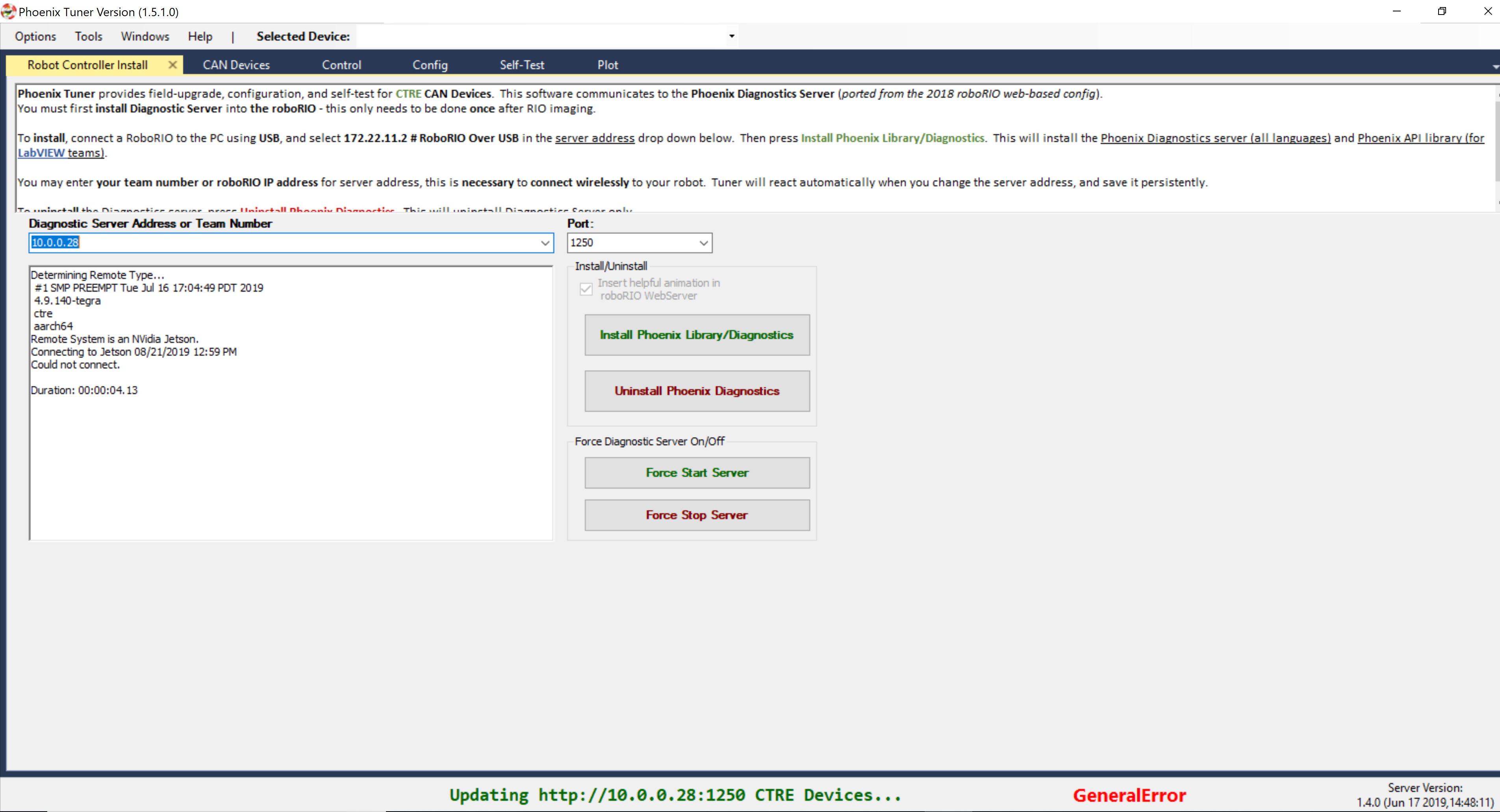

Connect both the Linux Robot Controller and Windows machine to the same network via WiFi or and ethernet connection.

Enter the IP Address or Name of the Linux Robot Controller into Phoenix tuner.

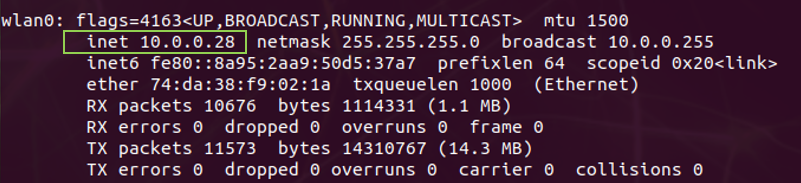

Tip

To find the IP address in Linux, run the ifconfig command to display network interfaces. The IP address will be listed under a ‘lan’ or ‘wlan’ entry and listed as inet.

Setting up the Phoenix Diagnostics Server¶

The Phoenix Diagnostics Server is an HTTP server that communicates with the Phoenix Tuner. There are two versions of the server: a standalone version installed through Phoenix Tuner (legacy), and a version built into your user program (latest). Only one version of the diagnostics server may be running at any given time. We recommend you run the diagnostics server through your user program.

You can disable the diagnostics server in your program by adding c_SetPhoenixDiagnosticsStartTime(-1); to the start

of your main method. The line is commented out in the example program.

Warning

The instructions below are available for legacy support. We recommend you instead run the Phoenix Diagnostics Server in your user program.

Warning

The legacy instructions below currently do not work. See: https://github.com/CrossTheRoadElec/Phoenix-Linux-SocketCAN-Example/issues/15

To install the standalone diagnostics server:

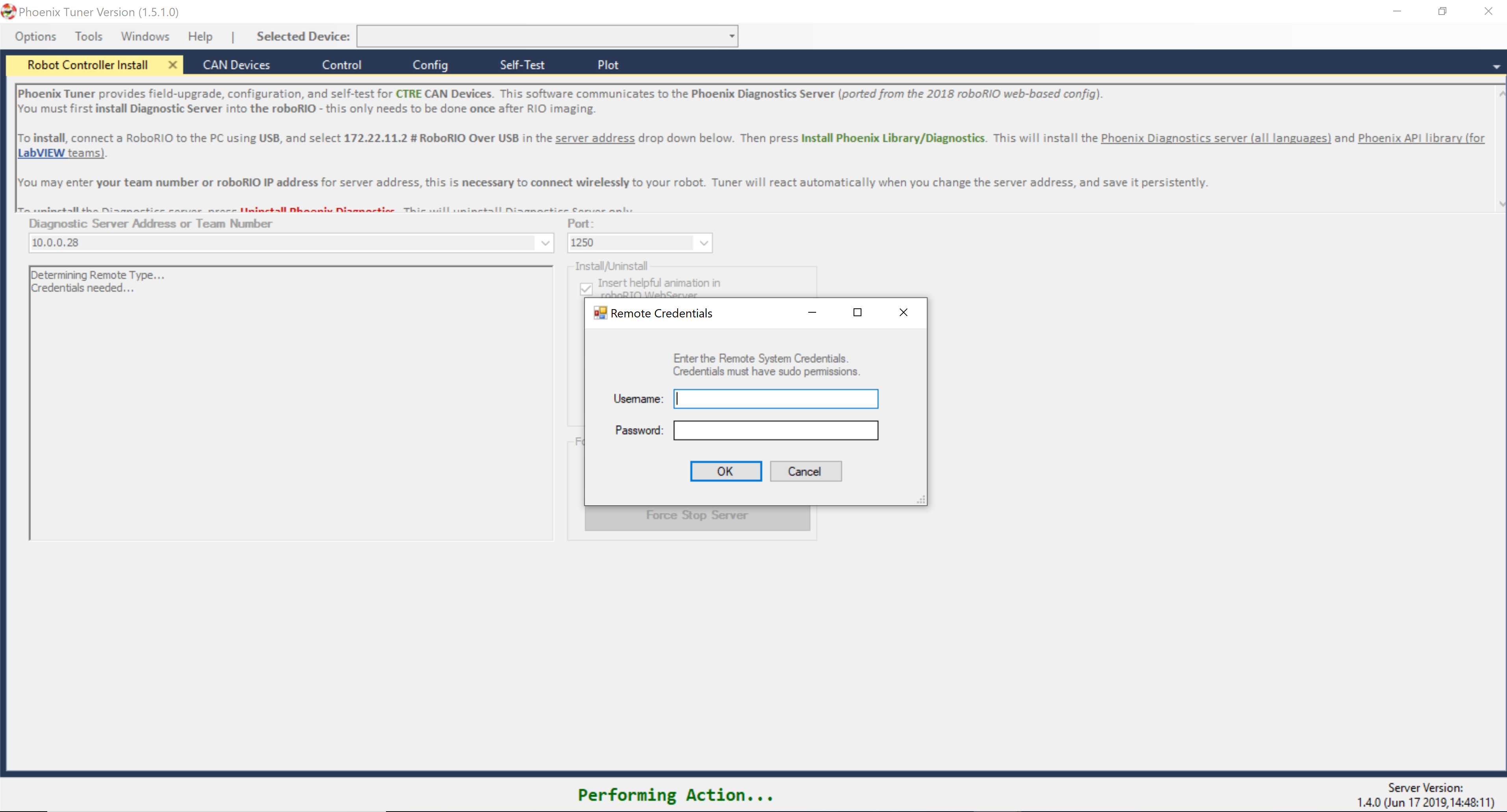

Press the Install button.

Enter your username and password when prompted.

Note

The user must have sudo permissions to successfully install.

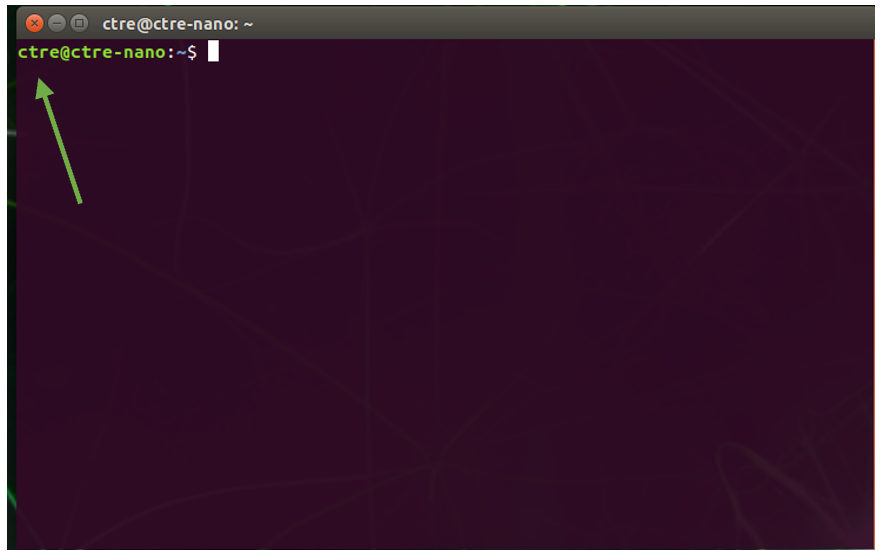

Note

To find your username look at the text before the @ in the terminal. For example, in this terminal the user is ctre.

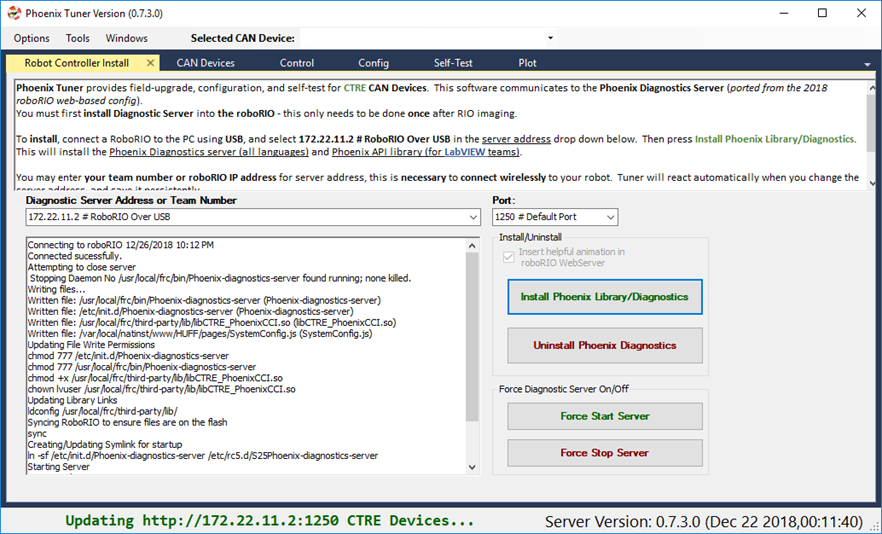

Tuner will then install and start the diagnostics server on the device.

The diagnostics server is now installed and running on your device.

Verify the robot controller - Tuner¶

After installation is complete, Tuner will immediately connect to your device.

Confirm the bottom status bar is green and healthy, and server version is present. If this is not the case, you may need to re-start the Diagnostic Server by using the “Force Stop Server” and “Force Start Server” buttons.

If there are CAN device present they will appear in the “CAN Devices” tab. However, it is possible that devices will appear to be missing - this will be resolved in “Bring Up: CAN Bus”.

Initial Hardware Testing¶

For your competition team to have the best chance of success, hardware components should be tested as soon as they are received. This is generally done by:

Powering up the device and confirming LED states.

Ensuring hardware shows up in Tuner if wired to CAN Bus.

Drive outputs / drive motor in both directions (if motor controller).

This is explained in the sections below, but it is worth pointing out how important this step is. It is in your team’s best interest to test ALL purchased robot components immediately and in isolation. Here are the reasons why:

Robot replacement components should be in a state of readiness. Otherwise a replacement during competition can yield erroneous behavior.

Many robot components (in general) have fixed warranty periods, and replacements must be done within them.

Confirming devices are functional before handing them to students ensures best chance of success. If a student later damages hardware, they need to understand how they did it to ensure it does not happen again. Without initial validation, you can’t determine root-cause.